What is NM550 abrasion resistant steel?

NM550 wear-resistant steel plate is a high-strength wear-resistant steel plate. The “NM” in the name is the pinyin abbreviation of the first letters of the word “wear-resistant”, and “550” represents its Brinell hardness value of about 550. The implementation standard is GB/T 24186-2022 “High-strength wear-resistant steel plates and steel belts for engineering machinery”.

NM550 Abrasion Resistant Steel Sheet Parameter

Chemical composition of NM 550 steel plate:

| C | Si | Mn | P | S | Cr | |

| 0.38 | 0.70 | 1.70 | 0.020 | 0.010 | 1.20 | |

| Mo | Ti | B total | Als (min) | Ni | ||

| 0.70 | 0.050 | 0.0005-0.006 | 0.010 | 1.00 | ||

NM 550 Wear Steel Plate Mechanical Properties:

| Tensile strength (≥Mpa) | -20℃ impacting test absorbed energy (Longi.J) | Elongation in ≥,% | HBW

Min |

| – | – | 50mm | 530 |

| – |

Characteristics and Properties of NM 550 Wear Plate:

High strength: can withstand greater pressure and impact, remain stable under high load conditions, and is not easy to deform or break.

High wear resistance: through reasonable chemical composition design and advanced production technology, the wear resistance is several times higher than that of ordinary steel plates, which can extend the service life of equipment and reduce maintenance costs.

Good processing performance: easy to cut, bend and weld, can be processed into parts of various shapes and sizes to meet the diverse needs of different industrial fields.

Where is NM 550 wear resistant metal used?

Mining machinery: used to manufacture wear-resistant parts of crushers, screening machines, conveyors and other equipment, such as liners, screen plates, bucket plates, etc., which can withstand huge impact and ore friction.

Engineering machinery: wear-resistant parts of excavators, loaders, bulldozers and other equipment are often made of NM550 steel plates, such as wear-resistant liners, blades, etc., which can cope with complex working conditions and materials.

Other fields: It is also widely used in environmental protection machinery, metallurgical machinery, coal mills in the power industry, etc.

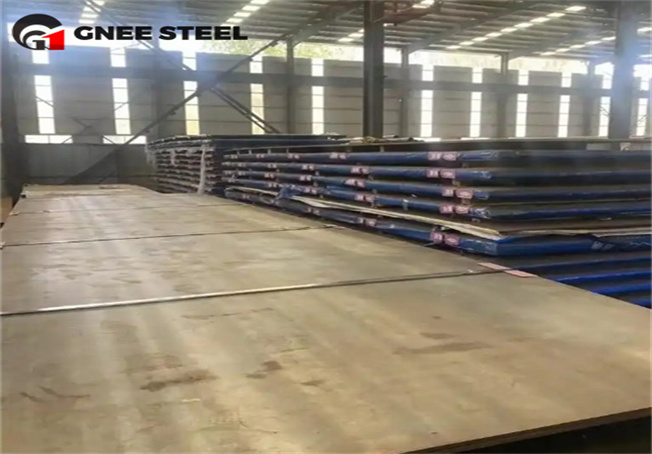

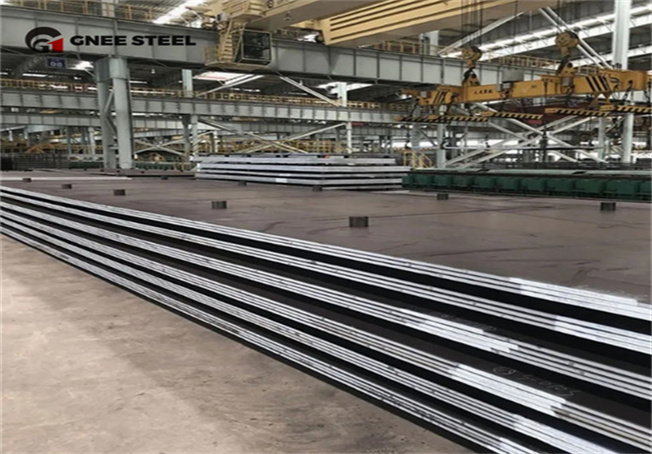

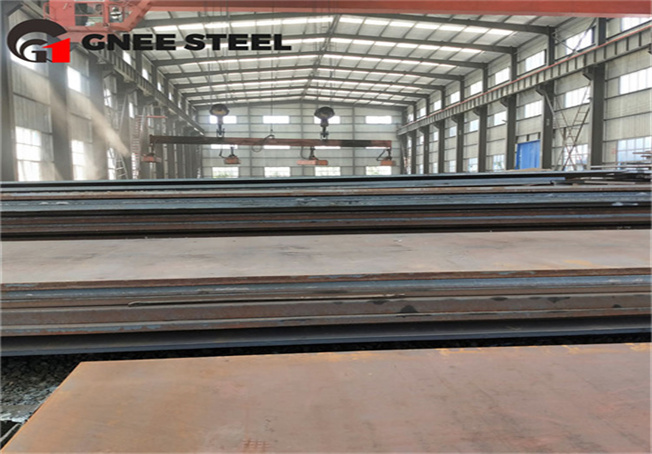

GNEE is a wear-resistant steel plate supplier with 18 years of production experience. The wear resistant steel we provide is strictly produced in accordance with the standards, has passed the quality certification, can provide quality certificates, and accept third-party testing.

GNEE can produce and supply structural steel according to your specific requirements, we can produce and customize any type and size of wear resistant steel plate according to your requirements. GNEE supports multi-specification and multi-brand steel plate customization.