What is NM 450 wear steel?

NM450 wear-resistant steel plate is a high-strength wear-resistant steel plate. “N” is the abbreviation of “resistant”, “M” is the abbreviation of “wear”, and “450” represents the Brinell hardness value HB value of about 450 (the domestic NM450 hardness value is usually between 420-480HBW).

NM450 Steel Plates Specification

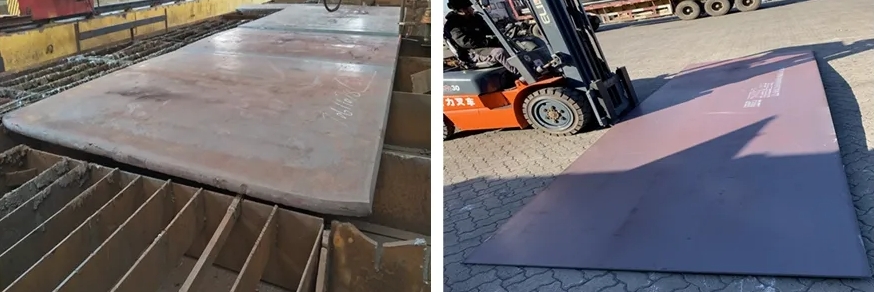

Thickness : 1.2mm-300mm

Width : 50mm-4020mm

Length : 50mm-18000mm

Production : Hot-Rolled (HR)

Standard : JIS G4051 GB711 YB/T107 ASTM

Hardness : Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

Material : NM 450, BHN 450 Steel Plate, NM450 Abrasion Resistant Steel Plates, NM450 Wear Resistant Plates

NM 450 Plate Processing

The majority of normal processing can be performed on NM 450 plate

- Electric Furnace Steelmaking

- LF Refining

- VD Vacuum Treatment

- Continuous casting and rolling

- Accelerated Cooling

- Thermal Treatment

- Ware-house-in Inspection

NM 450 Wear Resistant Plate Parameter

| NM450 Chemical Compositiom | |||||||||||

| Plate | C | Si | Mn | P | S | Cr | Ni | Mo | B | CEV | CET |

| thickness mm | max % | max % | max % | max % | max % | max % | max % | max % | max % | typv | typv |

| 3-(8) | 0.19 | 0.7 | 1.6 | 0.025 | 0.01 | 0.25 | 0.25 | 0.25 | 0.004 | 0.41 | 0.30 |

| 8-20 | 0.21 | 0.7 | 1.6 | 0.025 | 0.01 | 0.50 | 0.25 | 0.25 | 0.004 | 0.47 | 0.34 |

| (20)-40 | 0.23 | 0.7 | 1.6 | 0.025 | 0.01 | 1.00 | 0.25 | 0.25 | 0.004 | 0.57 | 0.37 |

| (40)-50 | 0.23 | 0.7 | 1.6 | 0.025 | 0.01 | 1.40 | 0.25 | 0.60 | 0.004 | 0.59 | 0.36 |

| (50)-80 | 0.26 | 0.7 | 1.6 | 0.025 | 0.01 | 1.40 | 1.00 | 0.60 | 0.004 | 0.72 | 0.41 |

| Mechanical properties of NM 450 | |||||

| Thickness/mm | ReL /MPa | Rm /MPa | A/% | Hardness/ HBW10/3000 | Impact -20℃ /J |

| 8 | 1250 | 1460 | 16 | 445 | 40 |

| 12 | 1290 | 1470 | 17 | 462 | 43 |

| 20 | 1370 | 1450 | 17 | 473 | 42 |

| 25 | 1230 | 1480 | 16.5 | 465 | 43 |

Advantages of NM 450 Wear Steel Plate

High wear resistance: high surface hardness, can effectively resist wear and scratches, can withstand heavy loads and impact loads, greatly reducing wear and maintenance costs.

Impact and fatigue resistance: can absorb a lot of energy when impacted, reduce equipment damage, and is not prone to fatigue damage after long-term use, ensuring stable operation of the equipment.

Good processing and welding performance: can easily perform processing operations such as cutting, bending, and welding, and is not prone to cracks or deformation

Where is NM 450 abrasion resistant wear plates used?

The series of NM wear-resistant steel combined the properties including high strength, high hardness, high wear resistant, weldable, bendable and mainly applied in:

- Edge of loaders in loader industry

- Wear-resistant lining plate in crusher industry.

- Slat type conveyer in colliery mechanical industry.

- Lining plate of coal pulverizer in power industry.

- Lining plate of hopper for heavy handling truck.

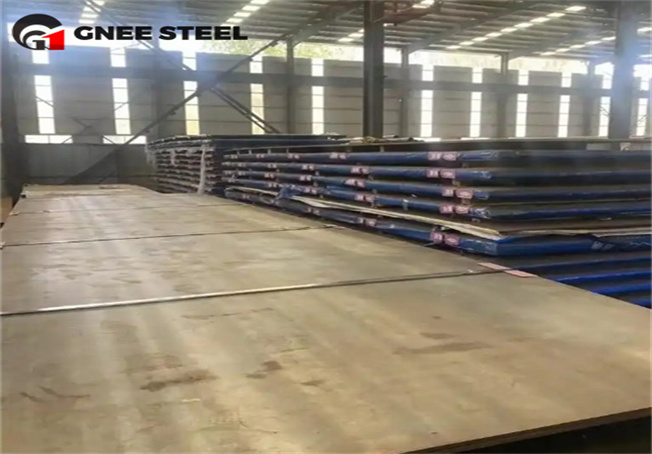

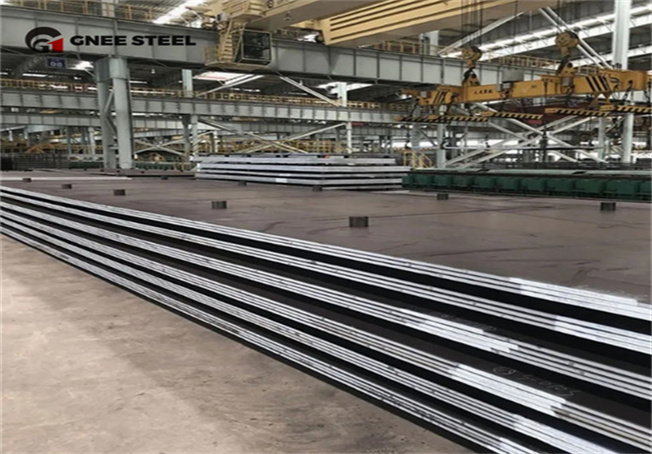

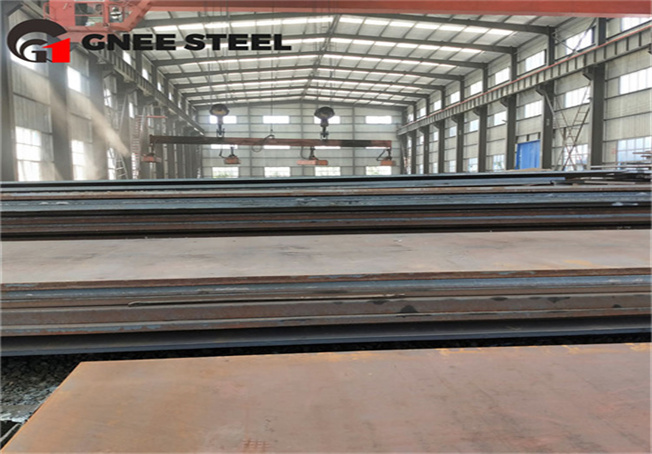

GNEE Steel is an abrasion steel manufacturer, wear steel plate supplier and resistant steel exporter, we are a company with 18 years of production experience, dedicated to providing abrasion plates of various materials.

As an ISO-certified company, we produce a large number of wear resistant steel products and have a large number of international customers. The ar steel we provide to customers can be customized in size according to needs and is used in many industries such as construction, bridges, marine, and manufacturing.