BY  GENN

GENN

2026/01

News

What is the difference between AR 400 and AR 450?

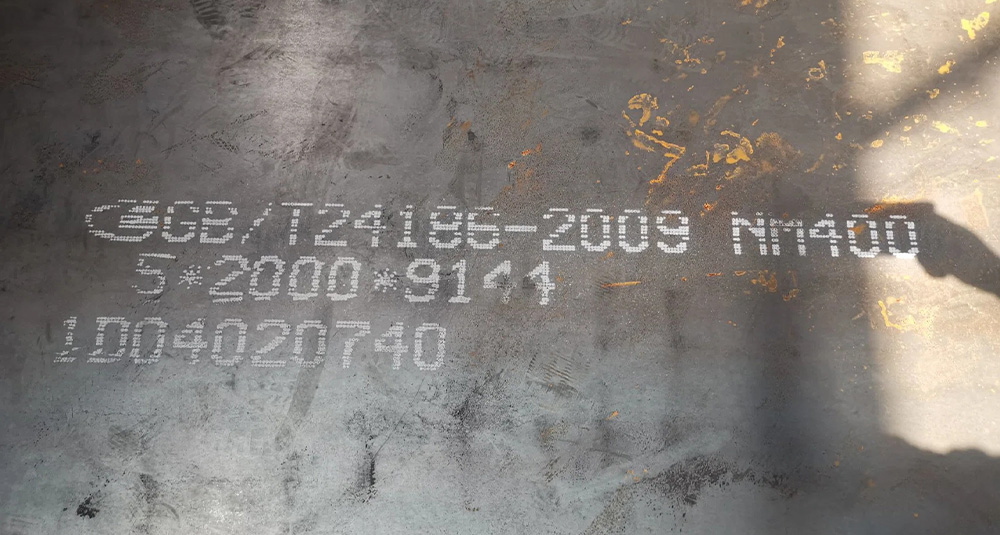

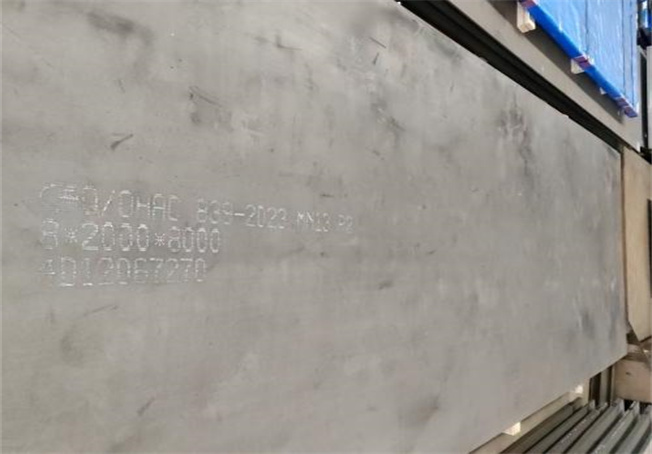

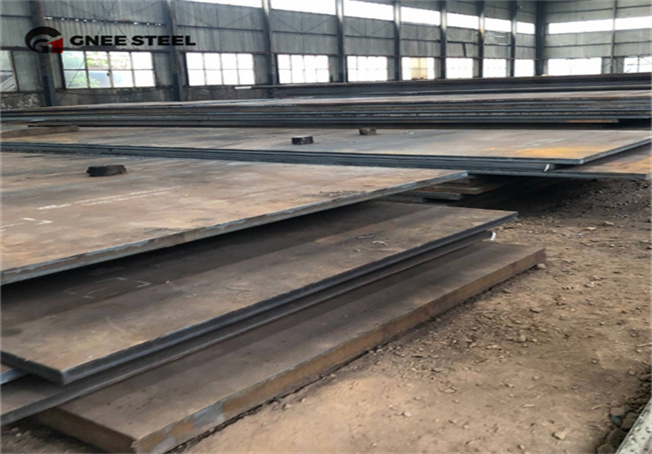

AR400 steel plate is a premium abrasion resistant steel designed for applications exposed to extreme wear, friction, and impact. As a professional steel plate manufacturer, GNEE supplies AR400 and AR400F abrasion resistant steel plates with stable hardness, reliable mechanical properties, and consistent quality for global industrial projects.

Within the first 100 words, it is important to clarify that GNEE is a manufacturer, not a distributor. Our AR400 steel plates are produced under strict quality control, supported by Mill Test Certificates (MTC), mechanical testing, and optional third-party inspection. With stable production capability and export experience, we help customers reduce downtime and extend equipment service life.

What Is AR400 Steel Plate Used For?

AR400 steel is known for its high hardness and exceptional wear resistance, making it ideal for environments where ordinary carbon steel fails quickly. The “400” refers to its approximate Brinell hardness, which delivers an excellent balance between abrasion resistance and impact toughness.

Typical uses of AR400 abrasion resistant steel plate include:

-

Mining and material handling systems

-

Construction and earth-moving equipment

-

Agricultural machinery

-

Industrial conveyors and hoppers

Compared with mild steel, AR400 steel plates significantly reduce replacement frequency and maintenance costs.

AR400F Steel Plate – Formable Abrasion Resistant Steel

For projects requiring better fabrication performance, AR400F steel plate offers enhanced formability while maintaining excellent wear resistance. The “F” stands for Formable, meaning this grade is easier to bend and shape compared to standard AR400.

Key advantages of AR400F include:

-

Improved cold forming capability

-

Reduced risk of cracking during bending

-

Reliable toughness without sacrificing hardness

AR400F is especially suitable for complex components such as curved liners, buckets, and formed wear parts.

Chemical Composition of AR400 Steel Plate

The performance of AR400 steel comes from carefully controlled alloying elements that enhance hardness and durability.

| Element | Typical Content (%) |

|---|---|

| Carbon (C) | 0.25 – 0.32 |

| Manganese (Mn) | 0.70 – 1.20 |

| Chromium (Cr) | 0.50 – 1.00 |

| Silicon (Si) | ≤0.70 |

| Phosphorus (P) | ≤0.025 |

| Sulfur (S) | ≤0.010 |

These elements work together to deliver high abrasion resistance and structural stability.

Mechanical Properties of AR400 / AR400F Steel Plate

AR400 and AR400F steel plates provide reliable mechanical performance for demanding wear applications.

| Property | Typical Value |

|---|---|

| Brinell Hardness | 360 – 440 HBW |

| Tensile Strength | 180 – 200 ksi |

| Yield Strength | ≥140 ksi |

| Elongation | ~10% |

| Impact Toughness | Good |

This balance of hardness and toughness allows AR400 steel to withstand abrasion and impact simultaneously.

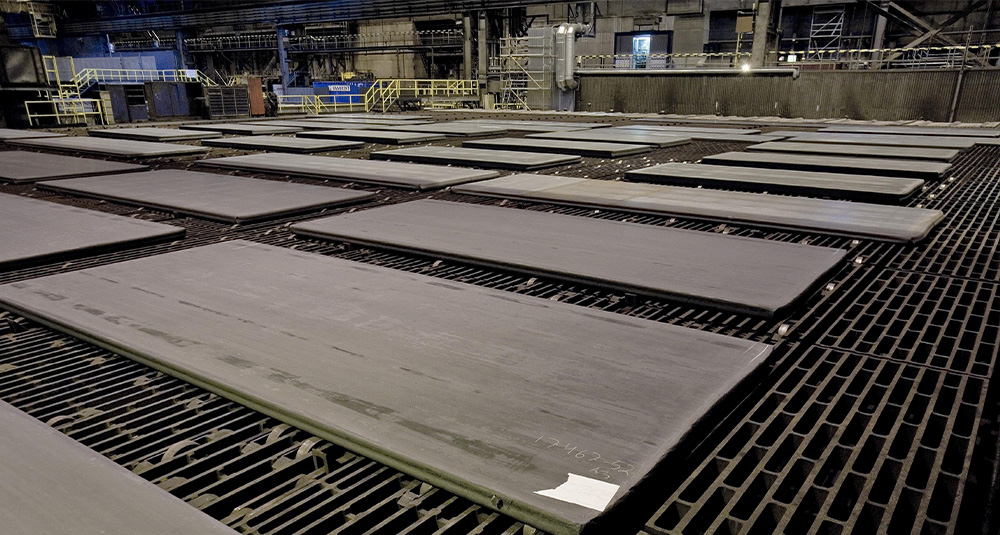

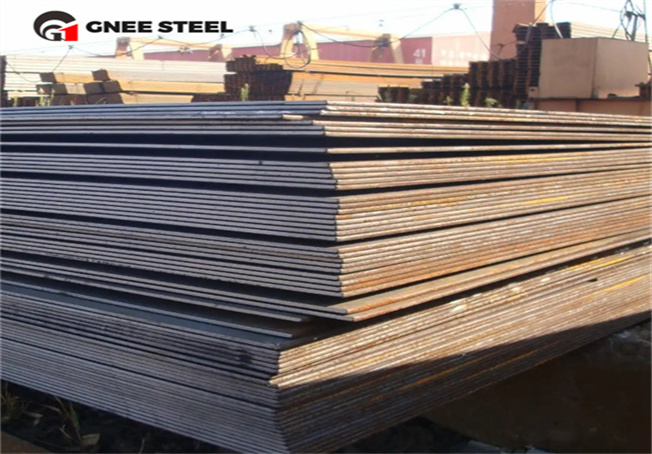

AR400 Steel Plate Size & Thickness Range

GNEE supplies AR400 and AR400F abrasion resistant steel plates in multiple sizes to meet project requirements:

-

Thickness: 3 mm – 100 mm

-

Width: 1500 mm – 4000 mm

-

Length: 3000 mm – 12000 mm

-

Delivery condition: Quenched & tempered

Custom cutting and profiling services are available.

Applications of AR400 Abrasion Resistant Steel Plate

AR400 steel plates are widely used across industries that demand durability and wear resistance.

Mining & Material Handling Applications

-

Dump truck liners

-

Chutes and hoppers

-

Buckets and wear plates

Construction Equipment

-

Loader buckets

-

Bulldozer blades

-

Dump truck beds

Agriculture & Industrial Use

-

Plow blades

-

Conveyor systems

-

Grain handling equipment

These applications benefit from longer service life and reduced maintenance downtime.

Processing AR400 Steel Plate: Cutting, Welding & Forming

AR400 steel plates can be effectively processed using proper techniques.

Cutting Methods

-

Plasma cutting

-

Laser cutting

-

Water jet cutting

Welding Recommendations

-

Preheating to reduce thermal stress

-

Controlled cooling after welding

-

Low-hydrogen consumables

Forming Tips

-

AR400F is preferred for bending

-

Preheating may be required for tight radii

Following correct procedures ensures structural integrity and performance.

AR400 vs AR450 vs AR500 Steel Plate Comparison

-

AR400 vs AR450: AR450 offers higher hardness but reduced formability.

-

AR400 vs AR500: AR500 is harder and more brittle, while AR400 provides better impact resistance and fabrication ease.

-

AR400 vs Mild Steel: AR400 is significantly more wear-resistant but harder to weld and form.

AR400 remains the most versatile choice for many wear applications.

Conclusion: Durable AR400 Steel Plate from a Trusted Manufacturer

In conclusion, AR400 steel plate and AR400F abrasion resistant steel plate provide an ideal balance of hardness, toughness, and workability for high-wear applications. From mining and construction to agriculture and industrial systems, AR400 steel helps extend equipment life and reduce operational costs.

As a reliable manufacturer, GNEE supplies fully tested AR400 steel plates with stable quality and global delivery capability.

👉 Contact us for latest AR400 steel plate price list and get professional support for your wear-resistant steel requirements.