BY  GENN

GENN

2024/06

News

NM 400 abrasion steel vs ar400 wear resistant steel

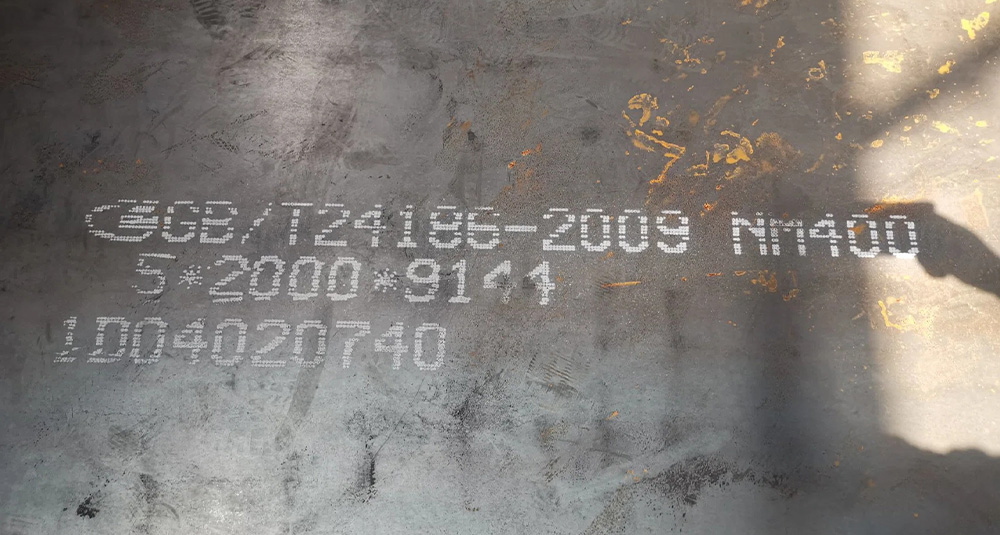

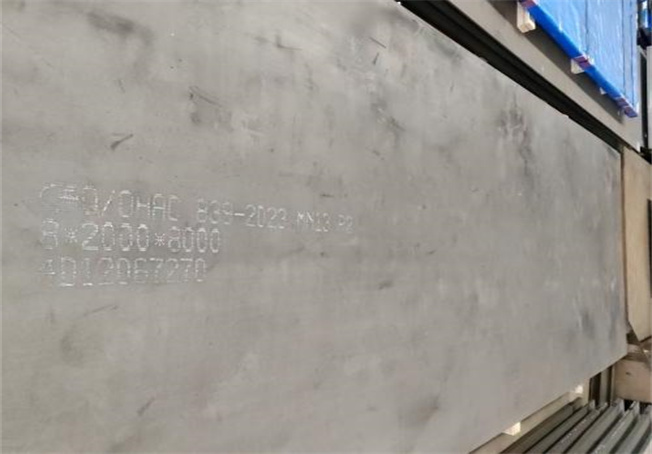

NM400 abrasion steel: The name is derived from the Chinese pinyin initials of “wear-resistant” (N-M), and the number “400” represents the average Brinell hardness (actual hardness range is 360-450 HB).

Implementing the Chinese standard GB/T 24186, delivery is mainly in the quenched and tempered (quenched + tempered) state.

AR400 abrasion resistant plate: The name is derived from the English abbreviation of “Abrasion Resistant”, and the number “400” represents the target Brinell hardness value (usually ≥360 HB).

Standard coverage

NM400 ar plate steel has both high strength and wear resistance (yield strength ≥900MPa, tensile strength ≥1100MPa); AR400 abrasion resistant steel emphasizes wear resistance and has slightly lower mechanical strength (typical yield strength ≥700MPa, tensile strength ≥900MPa).

Chemical composition and process comparison

| characteristic | NM400 abrasion plate | AR400 abrasion resistant plate |

|---|---|---|

| Main Ingredients | C: ≤0.25%,Cr: 0.4-0.6%,Mo: 0.4-0.5% | C: ≤0.3%, Mn: 1.0-1.5%

(some contain trace amounts of B and Ti) |

| Alloy design | High Cr and Mo content improves hardenability and wear resistance | Mainly carbon and manganese,

hardened by hot rolling process |

| Heat treatment process | Quenching + tempering

(quenching and tempering) |

Hot rolling/normalizing |

Hardness and wear resistance

NM400 resistant steel: surface hardness 360-450 HB, chromium carbide (Cr₇C₃) distribution enhances wear resistance (more than 20 times that of low carbon steel).

AR400: hardness 360-400 HB, relying on surface work hardening to improve wear resistance.

Strength and toughness balance

NM400 wear resistant steel: yield strength ≥900 MPa, -40℃ low temperature impact energy ≥50 J (thick plate optimized design).

AR400 wear steel plate: yield strength ≥700 MPa, slightly lower impact toughness (suitable for room temperature environment).