BY  GENN

GENN

2025/12

News

Gnee Delivers 1198 Tons Of A709 GR.345W Steel Plates And Welded Pipes For Vietnam

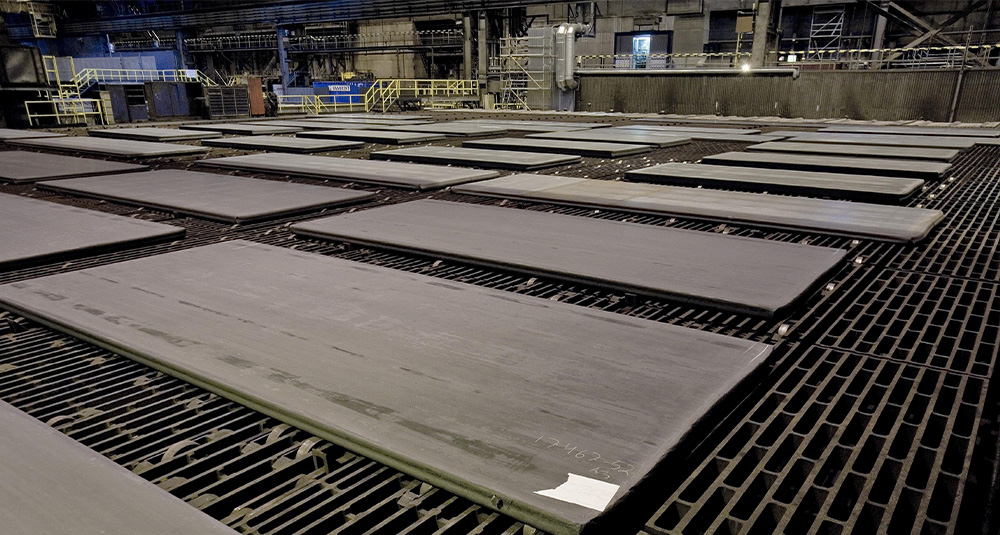

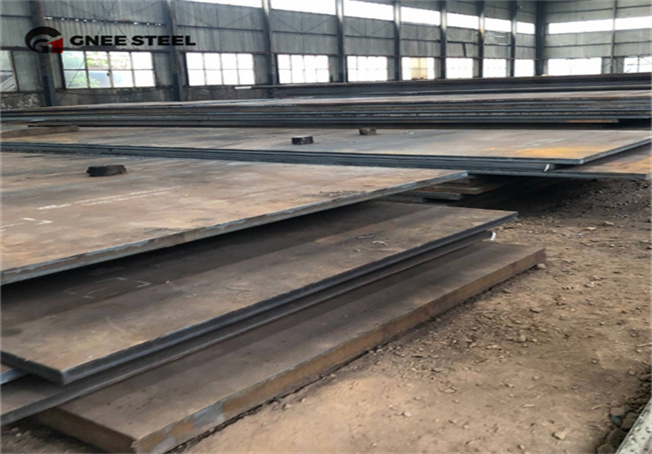

Gnee (Tianjin) Multinational Trade Co., Ltd has successfully delivered 1198 tons of ASTM A709 Grade 345W steel plates and welded pipes to Vietnam, providing essential materials for port infrastructure, industrial facilities, and coastal engineering projects.

The shipment reinforces Gnee’s position as a trusted supplier of high-strength, weathering-resistant steel in Southeast Asia.

Product Overview

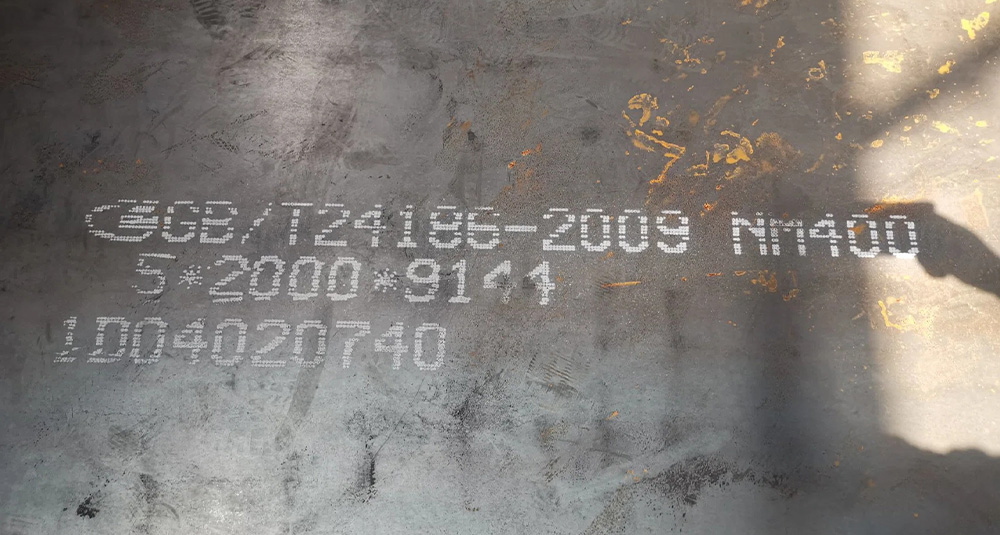

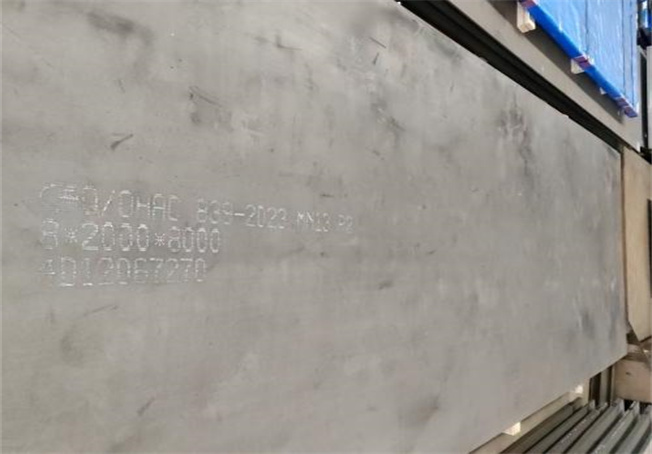

Material Standard: ASTM A709 GR.345W

Material Types:

Steel Plates: 6–45 mm thickness, 1000–2500 mm width

Welded Pipes: OD 150–600 mm, wall thickness 6–25 mm

Surface Treatment: Anti-corrosion oil; optional SA 2.5 sandblasting for outdoor or marine applications

Applications

A709 GR.345W steel plates and welded pipes in Vietnam are applied across port facilities, industrial structures, and coastal engineering projects:

Port Infrastructure

Plates used in dock decks, quay walls, and crane foundations.

Welded pipes act as pile supports, fender structures, and mooring frames.

Weathering steel resists saltwater corrosion, ensuring reduced maintenance intervals and longer service life.

Industrial Facilities

Steel plates form structural frameworks, load-bearing supports, and machinery foundations.

Pipes are applied as conduit supports, piping frameworks, and storage tank supports.

High strength and toughness guarantee stability under heavy machinery vibration and operational loads.

Coastal and Marine Engineering

Pipes and plates are used for sea wall structures, breakwaters, and floating dock components.

Corrosion resistance and toughness provide reliable performance in high-humidity and salt-laden air environments.

Reduces repainting and protective coating costs over the service life of marine structures.

Chemical Composition (%):

| Element | C | Mn | Si | P | S | Cu | Cr | Ni |

|---|---|---|---|---|---|---|---|---|

| Content | 0.16 | 1.22 | 0.31 | 0.06 | 0.03 | 0.33 | 0.49 | 0.35 |

Mechanical Properties:

| Property | ASTM Requirement | Gnee Test Result | Remark |

|---|---|---|---|

| Yield Strength | ≥345 MPa | 354–358 MPa | Exceeds standard |

| Tensile Strength | 480–620 MPa | 530 MPa | Uniform across batches |

| Elongation | ≥18% | 22% | Excellent ductility |

| Charpy Impact (–20°C) | ≥27 J | 35 J | Superior low-temperature toughness |

Production and Quality Control

Production Process:

Raw Material Selection: Certified steel billets for chemical and mechanical consistency.

Hot Rolling & Forming: Plates and pipes rolled to specified thickness and dimensions.

Welding & Normalization: Pipes welded with low-hydrogen electrodes; normalized to enhance toughness.

Surface Treatment: Anti-corrosion oil applied; optional SA 2.5 sandblasting for marine structures.

Dimensional Inspection: Laser measurement of thickness, straightness, and diameter tolerance (±0.5 mm).

Quality Testing:

| Test | Standard | Purpose | Result |

|---|---|---|---|

| Ultrasonic Flaw Detection | ASTM E213 | Detect internal defects | Passed |

| Hydrostatic Test | ASTM A530 | Verify pipe pressure resistance | Passed |

| Flattening/Bending Test | ASTM A370 | Confirm ductility and weld integrity | Passed |

| Coating Thickness | ISO 2178 | Ensure uniform protective layer | Passed |

| Third-party Verification | SGS | Independent inspection and certification | Certified |

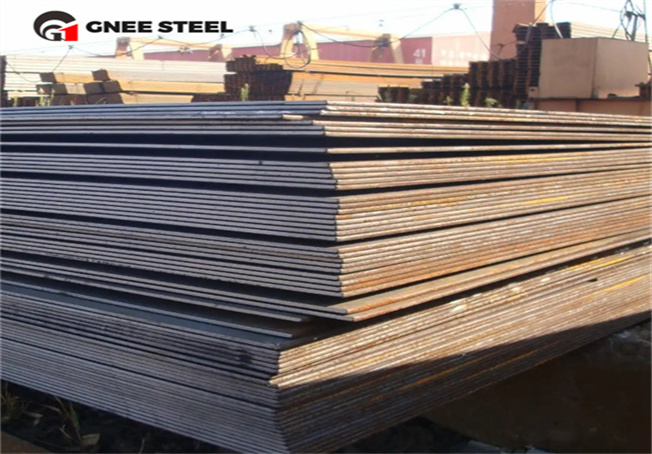

Packaging and Logistics

| Item | Details |

|---|---|

| Total Weight | 1198 tons |

| Packaging | Steel straps + waterproof plastic + anti-rust oil + wooden frames |

| Container Type | 40FT HQ and bulk shipment |

| Loading Port | Tianjin Xingang, China |

| Destination Port | Hai Phong, Vietnam |

| Transit Time | 14–15 days |

| Tracking | Real-time GPS monitoring and reporting |