BY  GENN

GENN

2026/01

News

Understanding the Difference: AR 400 vs. AR 500 Steel Plates

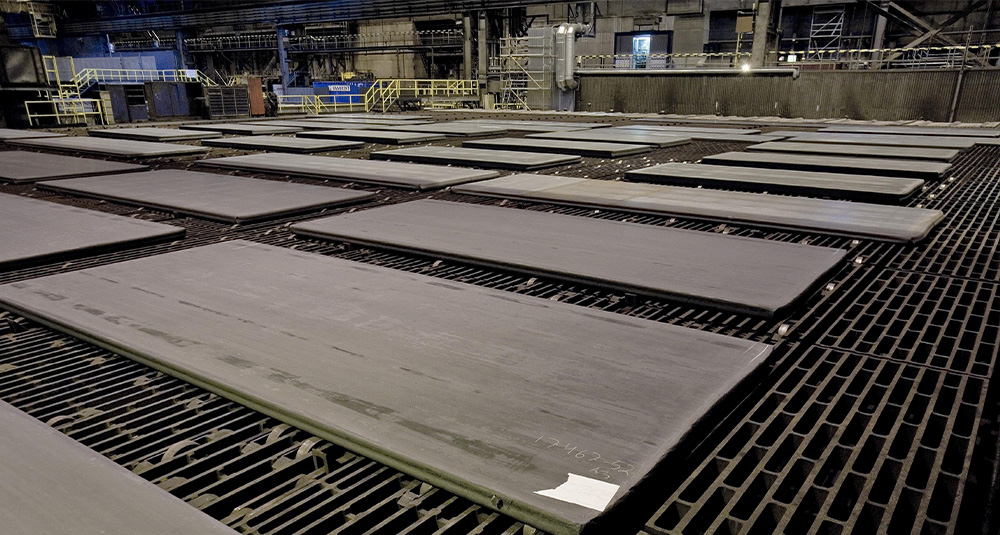

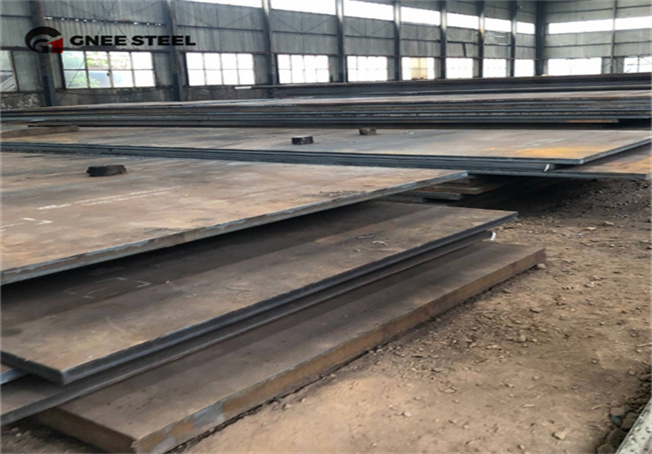

AR400 and AR500 steel plates are premium abrasion resistant steel materials engineered to perform under severe wear, friction, and impact conditions. As a professional abrasion resistant steel plate manufacturer, GNEE supplies AR400 and AR500 plates with stable hardness, controlled chemistry, and reliable mechanical performance for global industrial projects.

Within the first 100 words, it must be clear that GNEE is a manufacturer, not a reseller. Our AR400 and AR500 steel plates are produced under strict quality control systems, supplied with Mill Test Certificates (MTC), mechanical test reports, and optional third-party inspection. This ensures consistent performance even in the harshest operating environments.

Common Applications of AR400 and AR500 Steel Plates

Both AR400 and AR500 abrasion resistant steel plates are widely used across industries where wear resistance and durability are critical.

Mining & Material Handling Applications

-

Chutes and transfer points

-

Conveyors and liners

-

Buckets and ore pockets

Construction & Earth-Moving Equipment

-

Dump truck bodies

-

Loader buckets

-

Crushers and hoppers

Agricultural Machinery

-

Soil-contact components

-

Crop handling equipment

-

Wear parts exposed to sand and debris

Using AR steel plates significantly extends service life and reduces downtime compared to mild steel.

Key Mechanical Properties of AR400 and AR500 Steel Plate

Understanding mechanical properties is essential when selecting the correct abrasion resistant steel.

-

Hardness: Resistance to indentation and surface wear

-

Tensile Strength: Maximum stress the steel can withstand before breaking

-

Yield Strength: Stress level at which permanent deformation begins

-

Toughness: Ability to absorb impact energy without cracking

-

Ductility: Ability to deform without fracture

These characteristics directly affect performance in high-wear and high-impact environments.

AR400 vs AR500 Steel Plate – Main Differences Explained

Choosing between AR400 and AR500 depends on the operating conditions. Below is a detailed comparison.

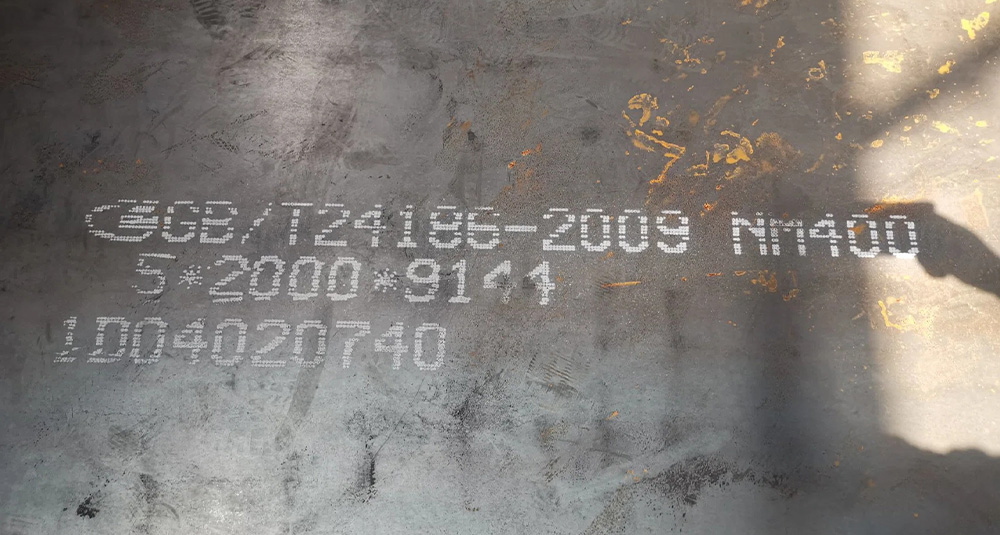

AR400 Steel Plate Properties

AR400 steel plate has a nominal hardness of 400 Brinell (HB). It offers an excellent balance between wear resistance and toughness.

-

Suitable for moderate to heavy abrasion

-

Higher toughness and ductility

-

Lower risk of cracking under impact

-

Easier to machine and form

Common AR400 applications include dump truck bodies, crushers, chutes, and hoppers.

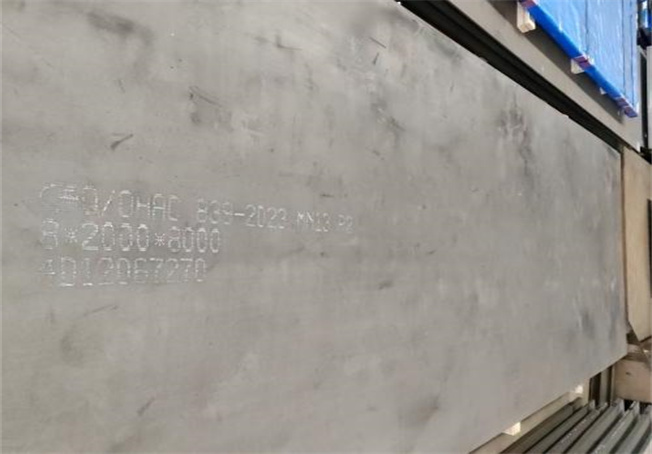

AR500 Steel Plate Properties

AR500 steel plate features a nominal hardness of 500 Brinell (HB), providing superior wear resistance.

-

Extremely high abrasion resistance

-

Best for sliding wear environments

-

Lower toughness compared to AR400

-

More prone to cracking under high impact

AR500 is often selected for ballistic plates, shooting targets, armor plating, and severe mining wear parts.

AR400 vs AR500 Steel Plate Mechanical Properties Comparison

| Property | AR400 Steel Plate | AR500 Steel Plate |

|---|---|---|

| Brinell Hardness | ~400 HB | ~500 HB |

| Wear Resistance | Moderate to Heavy | Very High |

| Toughness | Higher | Lower |

| Machinability | Easier | More difficult |

| Weldability | Good with precautions | Weldable with strict heat control |

This comparison helps engineers select the right abrasion resistant steel plate for their specific application.

Machinability and Weldability of AR400 and AR500 Steel Plates

Machining AR400 vs AR500

-

AR400 steel is easier to machine due to lower hardness

-

AR500 steel requires carbide tooling, slower speeds, and controlled feeds

Welding Considerations

Both AR400 and AR500 steel plates can be welded, but proper procedures are essential:

-

Preheating to reduce thermal stress

-

Controlled heat input during welding

-

Slow cooling to prevent cracking

Incorrect welding practices can compromise hardness and performance.

How to Choose Between AR400 and AR500 Steel Plate

Choose AR400 Steel Plate If:

-

The application involves high impact

-

Fabrication and machinability are important

-

Moderate to heavy wear resistance is sufficient

Choose AR500 Steel Plate If:

-

Maximum abrasion resistance is required

-

The application involves sliding abrasion

-

Impact loading is limited

Selecting the right grade improves performance and reduces lifecycle costs.

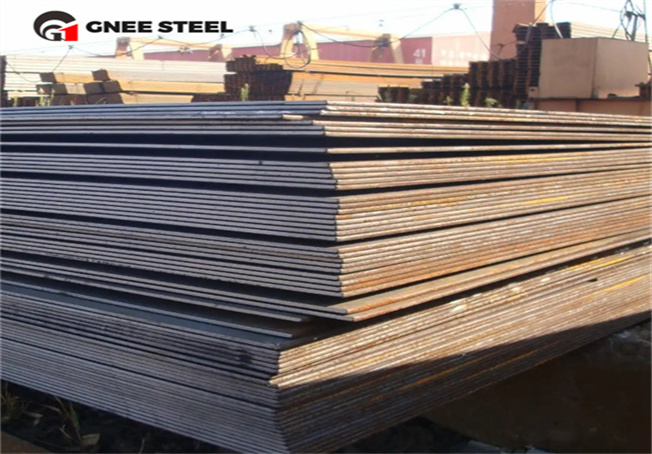

Why Choose GNEE AR400 and AR500 Steel Plates?

-

Manufacturer-direct supply

-

Stable hardness and wear resistance

-

Full inspection and certification

-

Custom cutting and profiling services

-

Global export experience

👉 Contact us for latest AR400 and AR500 steel plate price list

Conclusion: AR400 vs AR500 Steel Plate – The Right Solution for Wear Applications

In conclusion, AR400 and AR500 steel plates each serve distinct roles in abrasion resistant applications. AR400 steel plate offers superior toughness and fabrication ease, while AR500 steel plate delivers extreme wear resistance for severe environments. As a trusted abrasion resistant steel manufacturer, GNEE supplies both grades with consistent quality and professional technical support.

👉 Contact us for latest AR400 and AR500 steel plate price list and let our team help you choose the optimal solution for your project.