BY  GENN

GENN

2025/12

News

Gnee Welcomes Chinese Client Visit for NM500 Alloy Plate Purchase

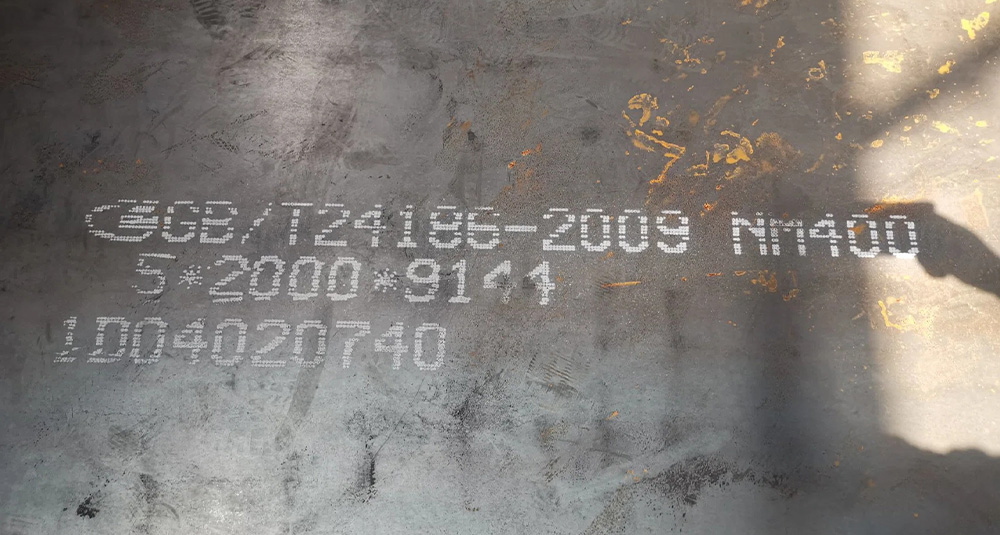

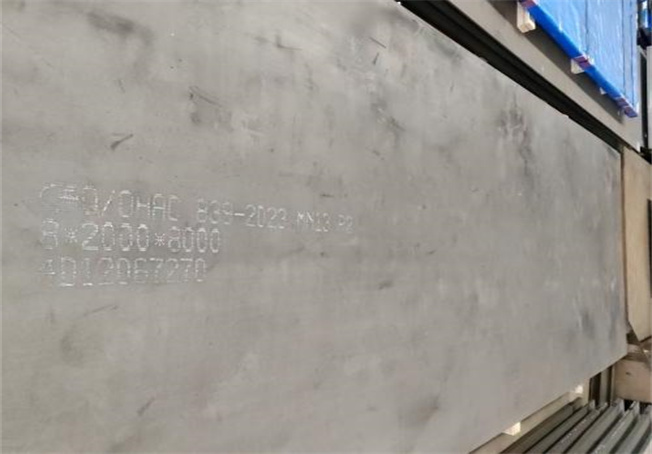

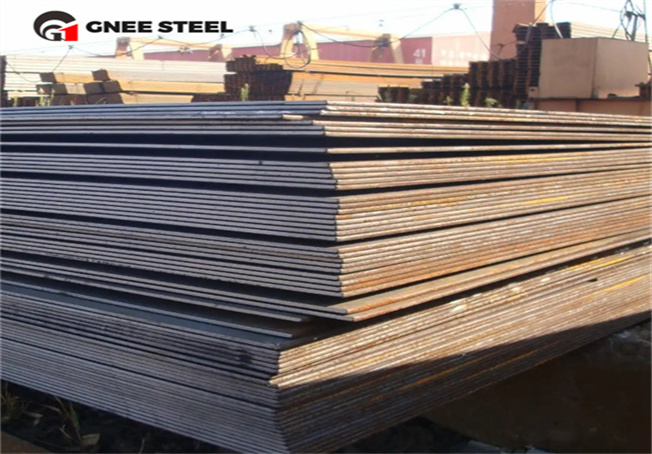

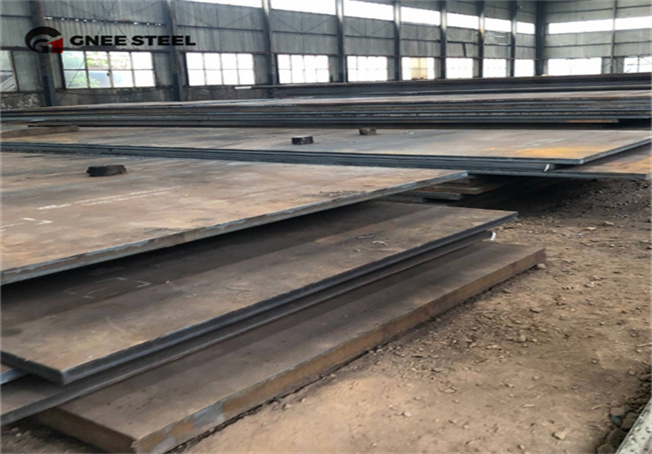

Gnee’s NM500 wear-resistant alloy plates are celebrated for their exceptional hardness, outstanding impact toughness, and consistent mechanical properties, making them widely utilized in mining machinery, construction equipment, conveyor systems, and heavy-duty structural applications.

Produced from high-grade steel through advanced smelting, precision hot rolling, rigorous heat treatment, and multiple quality inspections, NM500 plates deliver excellent wear resistance, dimensional accuracy, and surface flatness. Tailored processing options—including cutting, punching, and welding—enable the plates to meet unique client requirements, reduce maintenance expenses, and prolong service life.

NM500 Alloy Plate Technical Specifications

| Parameter | Unit | Value Range |

|---|---|---|

| Hardness | HB | 360–400 |

| Tensile Strength | MPa | ≥1100 |

| Impact Toughness | J (20℃) | ≥50 |

| Wear Resistance | HBW | ≥500 |

| Thickness Range | mm | 6–200 |

| Flatness | mm/2m | ≤3 |

| Dimensional Tolerance | % | ±2 |

Client Inquiry and Initial Engagement

Recently, a valued client from China contacted Gnee via email and phone to learn about NM500 plates’ technical specifications, performance attributes, and practical applications. The client prioritized wear resistance, thickness options, processing versatility, and logistics support, and expressed strong interest in our customized manufacturing capabilities. Gnee’s sales and engineering teams provided comprehensive brochures, test reports, and application case studies to illustrate NM500’s advantages in real-world scenarios.

Representative NM500 Applications

| Application | Product / Specification | Feature / Benefit |

|---|---|---|

| Mining Machinery | Bucket teeth, Crusher liners | Exceptional wear resistance, longer service intervals |

| Conveyor Systems | Conveyor plates, Liners | Superior flatness, high wear durability |

| Construction Equipment | Excavator & Loader wear parts | Excellent impact toughness, extended lifespan |

| Heavy-Duty Structures | Wear-resistant support plates | Reliable mechanical performance, reduced maintenance costs |

Consultation and Technical Discussion

Following initial interest, the client engaged with Gnee for detailed consultation regarding plate thickness, dimensional tolerances, surface finish, and special fabrication requirements. Our engineers explained NM500’s performance under various operating conditions and proposed optimized solutions, including reinforced hardened edges, customized cutting dimensions, and post-weld heat treatment, ensuring the material fully meets project-specific requirements.

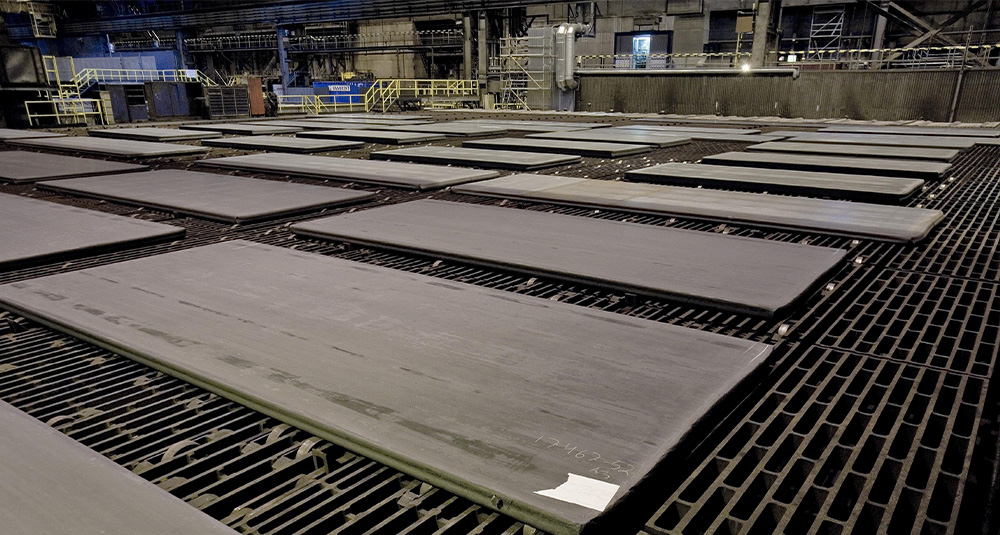

On-Site Visit and Facility Inspection

The client visited Gnee headquarters to tour the production facilities, observing the complete workflow from steel smelting, hot rolling, heat treatment, cutting, to final quality inspection. They highly appreciated Gnee’s ISO9001-certified quality system and efficient production capabilities. Live demonstrations included Rockwell hardness testing, impact tests, bending, and custom processing, providing the client with a firsthand understanding of product performance and flexibility.

Future Collaboration

The visit strengthened technical communication and reinforced the client’s confidence in Gnee’s product quality and service. Both parties look forward to enhanced cooperation on NM400, NM500, and other wear-resistant steel products.

Gnee remains committed to delivering high-performance steel materials and tailored solutions worldwide, helping clients achieve efficient project execution and sustainable long-term value.