BY  GENN

GENN

2025/11

Blog

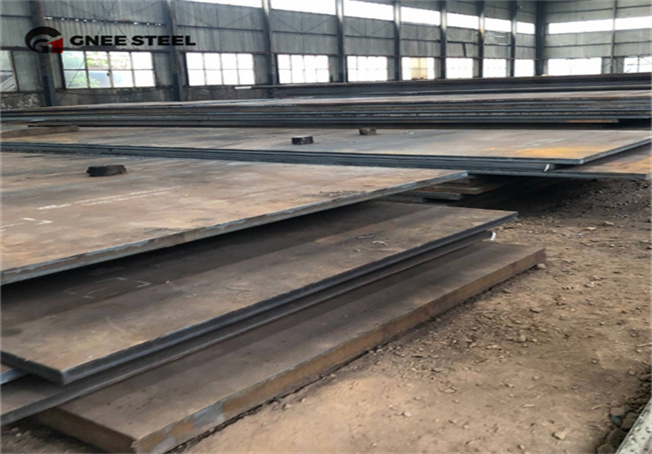

What is NM 400 material?

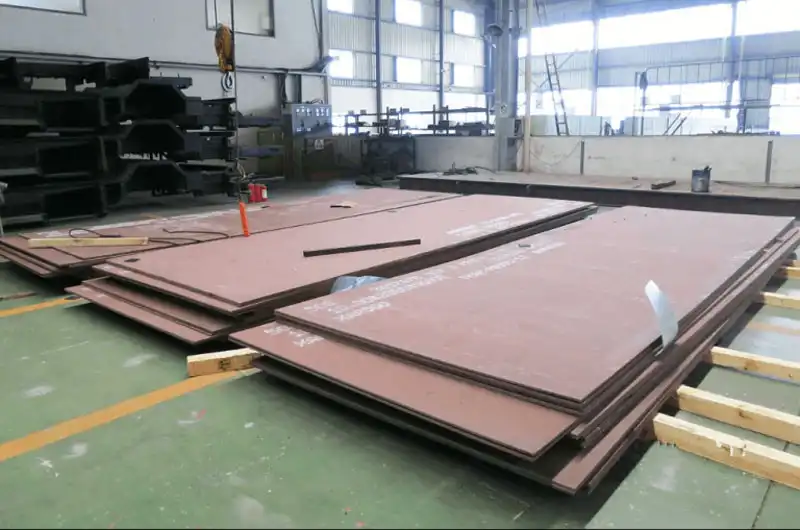

NM400 is a wear-resistant steel plate with a nominal hardness of 400 HBW, designed for applications requiring excellent abrasion resistance while maintaining good cold forming performance.

In addition, NM400 features excellent weldability, making it suitable for a wide range of fabrication needs.

Supplementary Technology:

Brinell hardness HBW is measured in accordance with EN ISO 6506-1, taken on a machined surface 0.5–2.0 mm below the plate surface. Hardness tests are performed per heat and per 40 tons, and for every thickness change of 15 mm within the same heat batch.

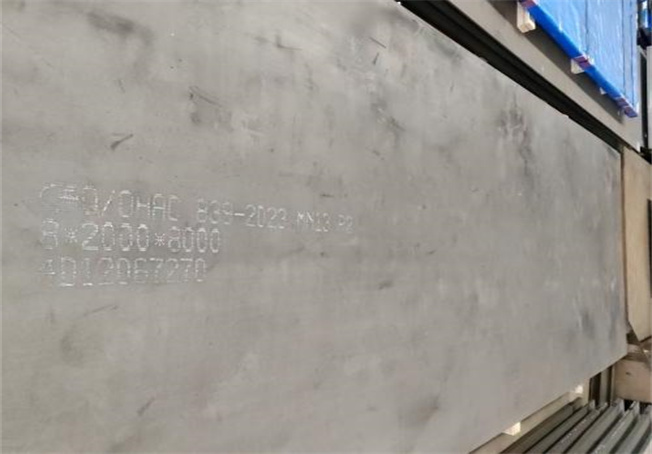

Available Dimensions:

-

Thickness: 3 mm – 130 mm

-

Width: 1500 mm – 4050 mm

-

Length: 3000 mm – 15000 mm

We specialize in supplying NM400 wear-resistant steel plates and can provide customized cutting and fabrication services upon request.

NM400 Chemical Composition (Max %)

| Thickness (mm) | C | Si | Mn | P | S | Cr | Ni | Mo | B | CEV (typ) | CET (typ) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3–8 | 0.15 | 0.70 | 1.60 | 0.025 | 0.01 | 0.30 | 0.25 | 0.25 | 0.004 | 0.33 | 0.23 |

| 8–20 | 0.15 | 0.70 | 1.60 | 0.025 | 0.01 | 0.50 | 0.25 | 0.25 | 0.004 | 0.37 | 0.27 |

| 20–32 | 0.18 | 0.70 | 1.60 | 0.025 | 0.01 | 1.00 | 0.25 | 0.25 | 0.004 | 0.48 | 0.29 |

| 32–45 | 0.22 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 0.50 | 0.60 | 0.004 | 0.57 | 0.31 |

| 45–51 | 0.22 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 0.50 | 0.60 | 0.004 | 0.57 | 0.38 |

| 51–80 | 0.27 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 1.00 | 0.60 | 0.004 | 0.65 | 0.41 |

| 80–130 | 0.32 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 1.50 | 0.60 | 0.004 | 0.73 | 0.48 |

Note: Plate thickness below 4 mm available upon special request.

CEV = C+Mn/6+(Cr+Mo+V)/5+(Cu+Ni)/15

CET = C+(Mn+Mo)/10+(Cr+Cu)/20+Ni/40

Mechanical Properties of NM400

| Grade | Yield Strength (min MPa) | Tensile Strength (MPa) | Elongation (min %) | Charpy V Impact (–40°C, longitudinal) J |

|---|---|---|---|---|

| NM400 | 1000 | 1250 | 10 | 45 |