BY  GENN

GENN

2025/08

Blog

What is AR500 steel equivalent to?

What is NM500 Steel?

NM500 Steel is one steel grade in GB standard GB 24186. NM 500 steel is a high-strength, wear-resistant / abrasion resistant steel known for its superior hardness and durability. This steel is specifically designed to withstand high wear conditions and provide extended service life in challenging environments.

With a hardness range of 470-540 HBW, NM500 is widely used in applications where resistance to abrasion is a primary concern, such as in mining equipment, construction machinery, and other heavy-duty applications.

The strength of NM500 wear-resistant steel is more than 3 times that of ordinary low-alloy steel plates, and the wear-resistant performance can be increased by 2-3 times, significantly extending the service life of the steel plates.

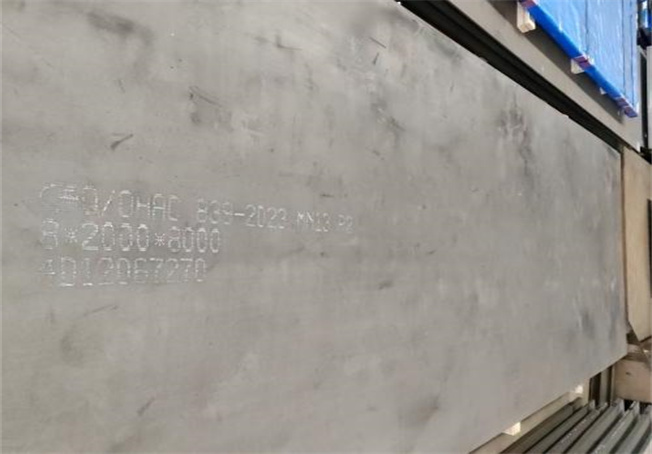

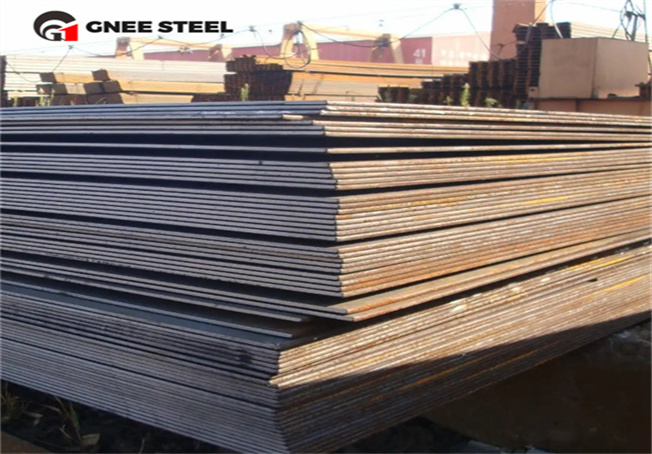

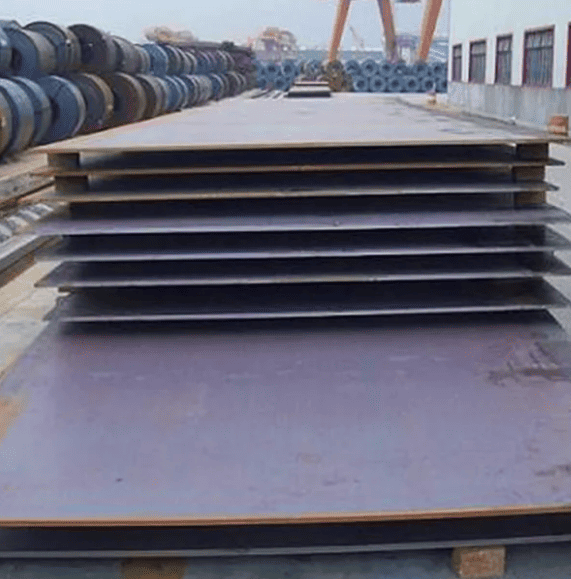

2. Supply Range of NM500 Steel

- NM500 Wear Resistant Plate: thickness 3mm ~ 100mm x 1500~2300mm width x L

- Black Surface: Black surface

- Condition: Q+T (prehard condition)

3. Relevant NM 500 Specification and Equivalent Steel Grades

| GBT 24186 | JFE | SUMITOMO | DILLIDUR | |

| NM500 | JFE-EH500 | K500 | 500 |

4. NM500 Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Ti | B | Als |

| NM500 | ≤0.38 | ≤0.70 | ≤1.70 | ≤0.020 | ≤0.010 | ≤1.50 | ≤1.00 | ≤0.65 | ≤0.50 | 0.0005-0.006 | ≥0.01 |

5. NM500 Steel Properties

NM500 steel exhibits excellent wear resistance due to its high hardness level. Some of its key properties include:

| Mechanical properties of NM 500 | |||

| Grade | Mechanical Property | ||

| NM 500 | Tensile | Elongation | |

| Mpa | Min % | ||

| 1350 | 7 | ||

| Charpy V Impact Test | |||

| Degree | longitudinal | ||

| -20 / -40 | J | ||

| min 21 | |||

| NM500 | Thickness | Hardness (HB) | |

| ≤70mm | 420~480 | ||

| >70~100mm | 450~540 | ||

6. Heat Treatment of NM500

- Quenching: Heat to 820-850°C, quench in oil or water.

- Tempering: Heat to 540-680°C, depending on the desired hardness.

NM500 plate is usually delivered as Q+T condition.

7. Application of NM500

NM500 steel is widely used in industries that require high wear resistance. Some of its primary applications include:

- Mining equipment

- Construction machinery

- Heavy-duty trucks

- Industrial machinery

- Wear plates and liners

NM500 wear-resistant steel plate can be used to produce various mechanical components such as: bearing races, crankshaft sleeves, piston rods, oil pump rotor bodies, cam pin linings; engine connecting rod bolts, nuts, washers and set screws; hydraulics Cylinder plunger ring, valve core seal; diesel engine cylinder head cover, valve lifter; tractor blade edge, chain rail joint lock block, mud scraper baffle, etc.