BY  GENN

GENN

2025/11

Blog

What are the properties of NM400 steel sheet?

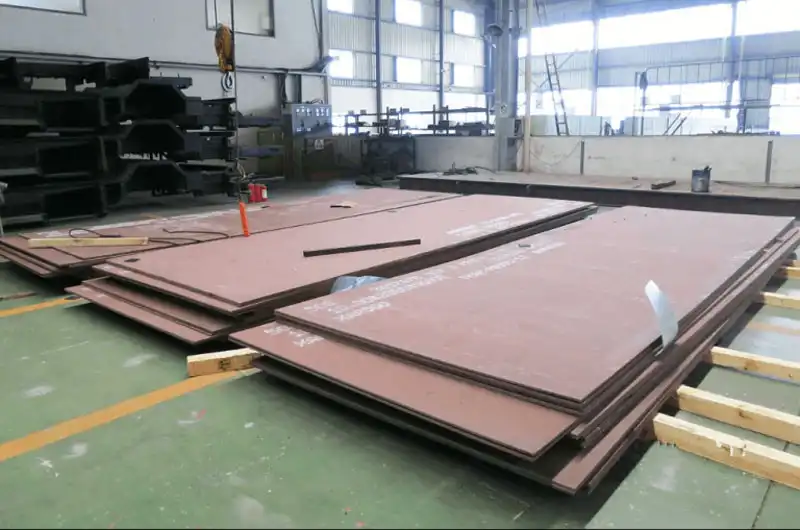

NM400 steel is a high-strength, wear-resistant steel grade engineered to deliver outstanding hardness, toughness, and durability. It is widely applied in harsh working environments where components are continuously exposed to abrasion, impact, and heavy mechanical loads.

Below are the key material properties of NM400 steel:

1. Hardness

NM400 steel features a typical hardness range of 360–440 HBW (Brinell Hardness).

This high hardness level provides:

-

Excellent resistance to indentation and surface abrasion

-

Enhanced performance under sliding wear

-

Superior protection against impact abrasive wear

Its hardness is one of the main reasons NM400 offers a significantly longer service life compared to ordinary structural steels.

2. Yield Strength

NM400 steel delivers a minimum yield strength of 1000 MPa, which ensures:

-

High resistance to deformation under load

-

Improved structural integrity

-

Reliable performance in high-stress applications

This property makes NM400 suitable for equipment that must maintain shape and stability under heavy operational forces.

3. Tensile Strength

With a typical tensile strength of around 1250 MPa, NM400 steel can withstand:

-

High levels of mechanical stress

-

Heavy static and dynamic loads

-

Challenging industrial environments

The strong tensile performance enables its use in demanding structural and wear-critical components.

4. Impact Resistance

Despite its high hardness, NM400 steel maintains excellent toughness.

It can withstand:

-

Sudden shocks

-

Impact loading

-

Abrasive particle strikes

This balance of hardness and toughness ensures that NM400 resists brittle fracture, even in dynamic or vibration-heavy conditions.

5. Wear Resistance

NM400 is specifically designed for superior abrasion resistance. It performs exceptionally well against:

-

Sliding wear

-

Impact wear

-

Particle erosion

This leads to:

-

Longer service life of parts

-

Reduced maintenance costs

-

Less downtime for equipment

6. Weldability

NM400 steel can be welded using conventional welding methods.

To ensure optimal performance:

-

Suitable welding procedures must be followed

-

Compatible filler materials should be used

-

Preheating or post-weld heat treatment may be required depending on plate thickness

Good weldability allows NM400 to be easily integrated into large equipment structures.

7. Formability

Although NM400 is a high-hardness grade, it still offers reasonable formability and can be processed using standard fabrication techniques:

-

Bending

-

Forming

-

Rolling

-

Cutting

This makes it versatile for manufacturing various complex shapes and customized wear-resistant components.

8. Common Applications

Thanks to its outstanding hardness, toughness, strength, and wear resistance, NM400 steel is widely used in industries such as:

-

Mining

-

Construction

-

Agriculture

-

Earthmoving machinery

-

Cement and aggregate processing

-

Mining trucks, chutes, buckets, crushers, conveyors, and hoppers

Typical components include:

-

Bucket liners

-

Dump truck bodies

-

Wear plates

-

Mixer blades

-

Conveyor liners

-

Chute and hopper liners

-

Bulldozer and excavator attachments

NM400 offers a cost-effective solution for extending equipment life, enhancing productivity, and reducing operational costs.

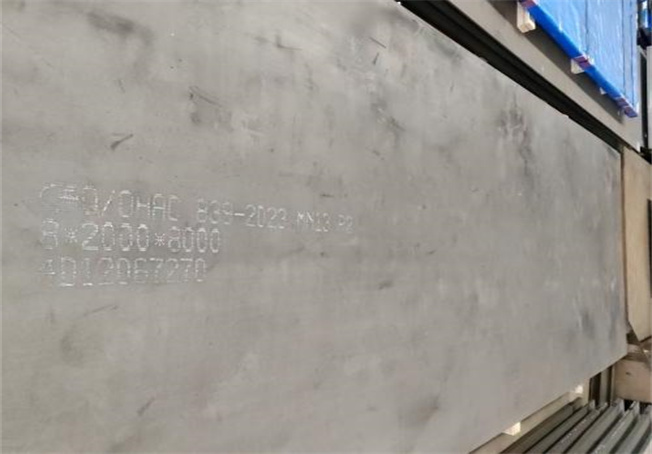

Note on Material Variations

The exact mechanical properties of NM400 steel may vary slightly depending on:

-

Manufacturer

-

Production process

-

Thickness

-

Heat treatment condition

For precise material specifications tailored to your application, consulting your steel supplier is recommended.