BY  GENN

GENN

2025/10

Blog

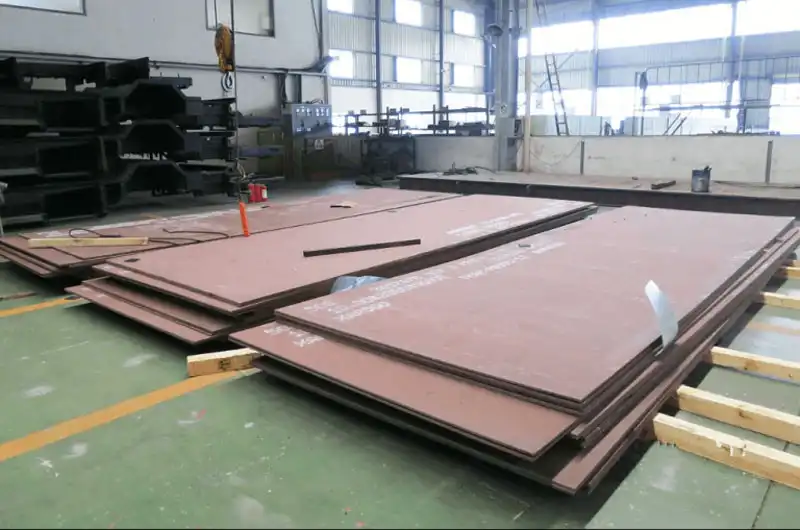

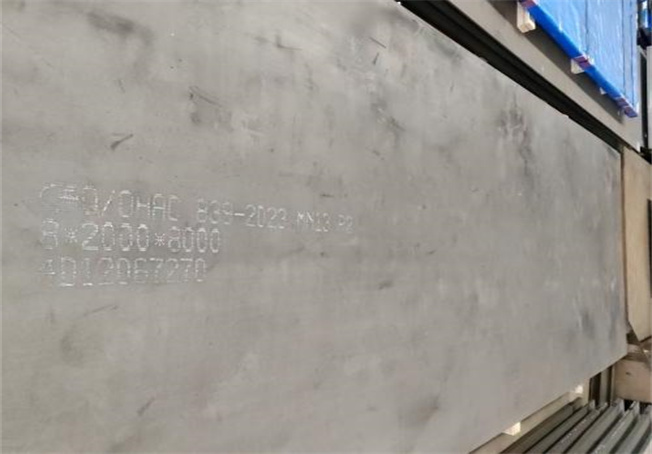

The Properties and Key Applications of AR400 wear resistance sheet plate

AR400 steel is a high-carbon alloy steel known for its exceptional hardness and wear resistance. Classified as a quenched and tempered steel, AR400 is primarily used in applications requiring high strength and durability. The primary alloying elements in AR400 include carbon (C), manganese (Mn), and silicon (Si), which significantly influence its mechanical properties and performance characteristics.

1 Comprehensive Overview

AR400 steel is categorized as a high-carbon alloy steel, specifically designed for applications that demand high wear resistance and toughness. The principal alloying elements are carbon, which enhances hardness, and manganese, which improves hardenability and tensile strength. The typical carbon content ranges from 0.28% to 0.34%, while manganese content is around 1.00% to 1.50%.

The most significant characteristics of AR400 steel include its high hardness, typically ranging from 360 to 440 Brinell hardness, and excellent wear resistance, making it suitable for heavy-duty applications such as mining, construction, and material handling. Its inherent properties also include good weldability and machinability, although these can be affected by the high carbon content.

Advantages:

– High Hardness: Provides excellent wear resistance, ideal for abrasive environments.

– Toughness: Maintains structural integrity under heavy loads.

– Weldability: Can be welded with appropriate techniques and filler materials.

Limitations:

– Brittleness: Higher hardness can lead to reduced ductility.

– Cost: Generally more expensive than lower-grade steels.

– Limited Corrosion Resistance: Not suitable for highly corrosive environments without protective coatings.

Historically, AR400 has been a preferred choice in industries such as mining and construction due to its ability to withstand harsh conditions and extend the lifespan of equipment.

2 Alternative Names, Standards, and Equivalents

| Standard Organization | Designation/Grade | Country/Region of Origin | Notes/Remarks |

|---|---|---|---|

| UNS | S42000 | USA | Closest equivalent to AR400 |

| AISI/SAE | 400 | USA | Commonly referenced in North America |

| ASTM | A514 | USA | Similar properties but different applications |

| EN | 10025-6 | Europe | Structural steel with different mechanical properties |

| DIN | 1.4000 | Germany | Minor compositional differences |

| JIS | G3106 | Japan | Equivalent for specific applications |

| GB | Q345B | China | Comparable in strength but different alloying elements |

| ISO | 6300 | International | General standard for high-strength steels |

The table above highlights various standards and equivalents for AR400 steel. It is essential to note that while these grades may be considered equivalent, subtle differences in composition and mechanical properties can affect performance in specific applications. For instance, while S42000 offers similar hardness, its lower manganese content may result in reduced toughness compared to AR400.

3 Key Properties

3.1 Chemical Composition

| Element (Symbol and Name) | Percentage Range (%) |

|---|---|

| C (Carbon) | 0.28 – 0.34 |

| Mn (Manganese) | 1.00 – 1.50 |

| Si (Silicon) | 0.15 – 0.40 |

| P (Phosphorus) | ≤ 0.025 |

| S (Sulfur) | ≤ 0.025 |

The primary role of the key alloying elements in AR400 steel is as follows:

– Carbon (C): Increases hardness and strength through the formation of carbides.

– Manganese (Mn): Enhances hardenability and tensile strength, contributing to overall toughness.

– Silicon (Si): Improves deoxidation during steelmaking and contributes to strength.

3.2 Mechanical Properties

| Property | Condition/Temper | Test Temperature | Typical Value/Range (Metric) | Typical Value/Range (Imperial) | Reference Standard for Test Method |

|---|---|---|---|---|---|

| Tensile Strength | Quenched & Tempered | Room Temp | 1380 – 1550 MPa | 200 – 225 ksi | ASTM E8 |

| Yield Strength (0.2% offset) | Quenched & Tempered | Room Temp | 1170 – 1300 MPa | 170 – 190 ksi | ASTM E8 |

| Elongation | Quenched & Tempered | Room Temp | 12 – 15% | 12 – 15% | ASTM E8 |

| Hardness (Brinell) | Quenched & Tempered | Room Temp | 360 – 440 HB | 36 – 44 HRC | ASTM E10 |

| Impact Strength | Quenched & Tempered | -20°C (-4°F) | 27 – 34 J | 20 – 25 ft-lbf | ASTM E23 |

The combination of these mechanical properties makes AR400 steel particularly suitable for applications involving high mechanical loading and structural integrity requirements. Its high tensile and yield strengths ensure that it can withstand significant forces, while its hardness provides resistance to wear and abrasion.

3.3 Physical Properties

| Property | Condition/Temperature | Value (Metric) | Value (Imperial) |

|---|---|---|---|

| Density | Room Temp | 7.85 g/cm³ | 0.284 lb/in³ |

| Melting Point | – | 1425 – 1540 °C | 2600 – 2800 °F |

| Thermal Conductivity | Room Temp | 46 W/m·K | 31.8 BTU·in/h·ft²·°F |

| Specific Heat Capacity | Room Temp | 0.49 kJ/kg·K | 0.12 BTU/lb·°F |

| Electrical Resistivity | Room Temp | 0.0000017 Ω·m | 0.0000017 Ω·in |

| Coefficient of Thermal Expansion | Room Temp | 11.5 x 10⁻⁶ /°C | 6.4 x 10⁻⁶ /°F |

Key physical properties such as density and thermal conductivity are significant for AR400 steel’s common applications. The high density contributes to its robustness, while the thermal conductivity allows for effective heat dissipation in applications involving high temperatures.

3.4 Corrosion Resistance

| Corrosive Agent | Concentration (%) | Temperature (°C/°F) | Resistance Rating | Notes |

|---|---|---|---|---|

| Chlorides | Varies | Ambient | Fair | Risk of pitting |

| Sulfuric Acid | 10% | 25°C (77°F) | Poor | Not recommended |

| Sodium Hydroxide | 5% | 25°C (77°F) | Fair | Risk of stress corrosion cracking |

| Atmospheric | – | Ambient | Good | Requires protective coating |

AR400 steel exhibits limited corrosion resistance, particularly in environments with chlorides and acids. It is susceptible to pitting and stress corrosion cracking, which can compromise its structural integrity over time. Compared to other steel grades, such as stainless steels (e.g., 304 or 316), AR400’s corrosion resistance is significantly lower, making it less suitable for applications in highly corrosive environments.

Typical Applications and End Uses

| Industry/Sector | Specific Application Example | Key Steel Properties Utilized in this Application | Reason for Selection (Brief) |

|---|---|---|---|

| Mining | Wear plates for crushers | High hardness, wear resistance | Extends equipment lifespan |

| Construction | Excavator buckets | Toughness, impact resistance | Handles heavy loads |

| Material Handling | Conveyor systems | Durability, wear resistance | Reduces maintenance costs |

| Agriculture | Tillage equipment | Hardness, strength | Enhances efficiency |

Other applications include:

– Heavy machinery components

– Railway track components

– Chassis for heavy trucks

AR400 steel is chosen for these applications due to its ability to withstand harsh conditions and provide longevity, ultimately leading to reduced downtime and maintenance costs.