BY  GENN

GENN

2025/12

Blog

NM500 VS AR500 Wear-resistant steel plate

Grade Origin

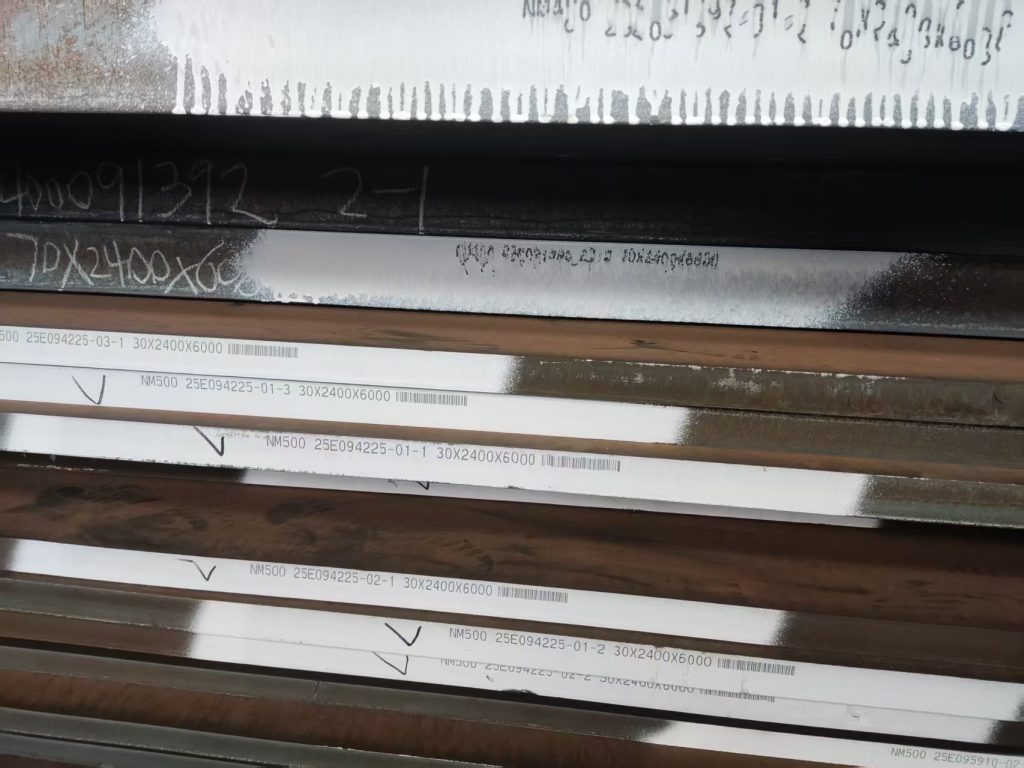

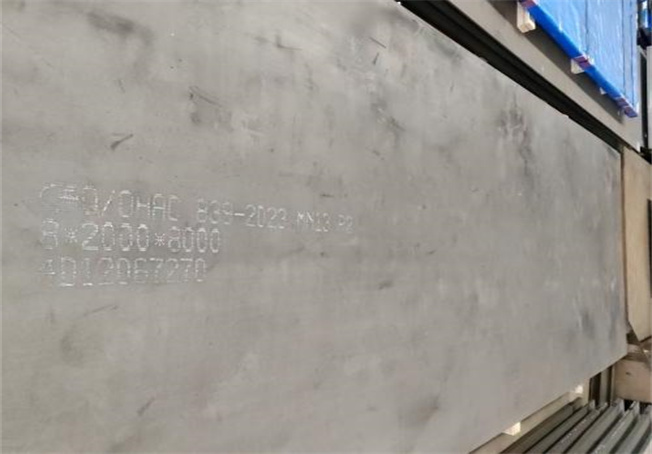

NM500 is a Chinese wear-resistant steel grade, where “NM” refers to Nai Mo 、, meaning abrasion-resistant, specified under GB/T 24186.

Key Technical Characteristics

-

Hardness

Typical Brinell hardness ranges from 470–530 HBW, with a nominal value of 500 HBW, ensuring excellent resistance to severe abrasive conditions. -

Wear Resistance

NM500 exhibits outstanding resistance to sliding wear, gouging, and surface abrasion, particularly in high-load environments. -

Mechanical Strength

Combines high tensile strength with adequate toughness, allowing it to withstand both abrasive wear and moderate impact loads. -

Manufacturing Process

Produced by quenching and tempering (Q&T) to achieve a uniform martensitic microstructure and stable hardness through the thickness.

Typical Mechanical Data (Reference Values)

| Property | Typical Value |

|---|---|

| Hardness | 470–530 HBW |

| Yield Strength | ≥ 1200 MPa |

| Tensile Strength | 1400–1600 MPa |

| Elongation | ≥ 10% |

| Impact Toughness (−20°C) | ≥ 24 J |

AR500 Abrasion Resistant Steel Plate

Grade Origin

AR500 is a general designation for abrasion-resistant steel widely used in international markets. “AR” stands for Abrasion Resistant.

Key Technical Characteristics

-

Hardness

Standard hardness level is 480–540 BHN, typically controlled around 500 BHN. -

Wear Performance

AR500 is well-known for its superior resistance to sliding abrasion and impact wear, making it suitable for harsh service conditions. -

Strength and Toughness

Provides a balanced combination of high strength and reasonable impact resistance, suitable for heavy-duty wear applications. -

Manufacturing Standards

Commonly produced in accordance with ASTM-related practices, often compared with or supplied under specifications such as ASTM A514 (for Q&T high-strength plates).

Typical Mechanical Data (Reference Values)

| Property | Typical Value |

|---|---|

| Hardness | 480–540 BHN |

| Yield Strength | 1100–1300 MPa |

| Tensile Strength | 1300–1600 MPa |

| Elongation | 8–12% |

| Impact Toughness | Application-dependent |

NM500 vs AR500 – Technical Comparison

Hardness Level

Both NM500 and AR500 maintain hardness values close to 500 Brinell, providing comparable resistance to abrasive wear.

Abrasion Resistance

Each grade performs exceptionally well in environments involving:

-

Sliding abrasion

-

Repeated material contact

-

High surface wear rates

Service life in wear applications is often 3–5 times longer than that of conventional structural steels (e.g., Q235 or A36).

Strength Performance

Both materials offer high tensile and yield strength, enabling:

-

Reduced plate thickness

-

Lower structural weight

-

Improved load-bearing efficiency

Standards and Specifications

| Item | NM500 | AR500 |

|---|---|---|

| Standard System | GB/T 24186 | ASTM / International |

| Hardness Range | 470–530 HBW | 480–540 BHN |

| Heat Treatment | Quenched & Tempered | Quenched & Tempered |

| Typical Market | China / Asia | North America / Global |

Typical Applications

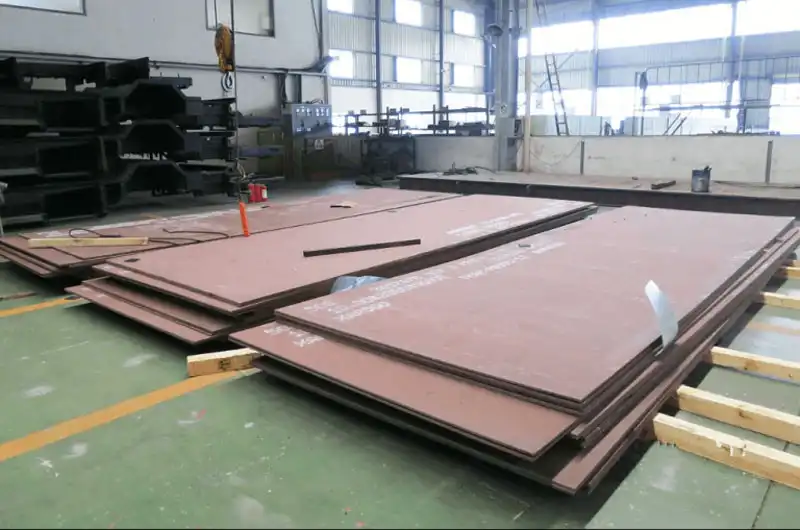

NM500 and AR500 are widely used in:

-

Mining and quarry equipment

-

Dump truck bodies and liners

-

Excavator buckets and blades

-

Construction and earthmoving machinery

-

Chutes, hoppers, and wear plates

Both materials are ideal for high-wear, high-impact operating environments where extended service life and reduced maintenance are critical.

Availability and Selection Considerations

Material selection between NM500 and AR500 is usually influenced by:

-

Required standard compliance

-

Local supply chain and lead time

-

Project documentation requirements

-

Customer or engineering preferences

NM500 and AR500 wear-resistant steel plates demonstrate equivalent hardness levels, similar mechanical strength, and comparable abrasion resistance.

Performance differences are minimal in most applications. The final choice is typically based on standard system, market availability, and project specifications, rather than intrinsic material capability.