BY  GENN

GENN

2025/08

Blog

NM500 VS AR500 Wear-Resistant Steel Plate Analysis

NM500 and AR500 are two widely recognized abrasion-resistant steel plates used in industries where wear resistance, impact strength, and durability are critical.

While they share similar hardness and performance characteristics, they are produced under different standards and have subtle differences in composition, toughness, and availability.

1. Origin and Standards

-

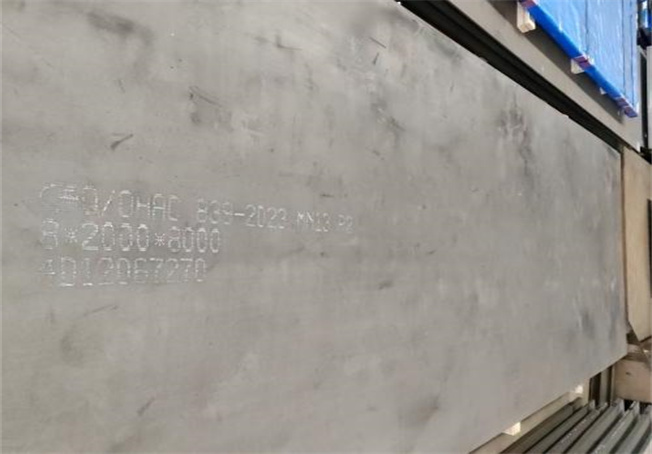

NM500 Steel Plate

-

Standard: Chinese standard GB/T 24186

-

Meaning: “NM” stands for Nai Mo (耐磨), meaning “wear-resistant” in Chinese.

-

Production: Manufactured in China, widely used in mining, construction, and heavy machinery.

-

-

AR500 Steel Plate

-

Standard: American standard, typically produced according to ASTM specifications (e.g., ASTM A514, ASTM A572).

-

Meaning: “AR” stands for Abrasion Resistant.

-

Production: Widely recognized in the US and international markets, especially in shooting targets, armor, and heavy-duty industrial equipment.

-

2. Chemical Composition and Properties

While exact chemical compositions vary by manufacturer, both NM500 and AR500 are high-carbon manganese steels designed for wear resistance.

| Property | NM500 Steel Plate | AR500 Steel Plate |

|---|---|---|

| Standard | GB/T 24186 (China) | ASTM Standards (USA) |

| Typical Hardness | ~500 HBW | ≥477–500 BHN |

| Abrasion Resistance | Excellent | Excellent |

| Tensile Strength | High | High |

| Impact Toughness | Better than AR500 | Good, slightly lower |

| Availability | Mainly in China | Widely global, especially US |

3. Hardness and Wear Resistance

-

NM500: Typically has a Brinell hardness around 500 HBW, offering outstanding wear resistance and longer service life in abrasive conditions.

-

AR500: Has a minimum Brinell hardness of 477 HB (often around 500 BHN), meeting ASTM performance standards for abrasion resistance.

Both grades perform exceptionally well in high-wear environments such as mining chutes, dump truck beds, and earthmoving equipment.

4. Impact Toughness

One key difference is impact performance:

-

NM500 steel generally offers better impact toughness, meaning it can absorb higher impact forces without cracking.

-

AR500 steel is also impact-resistant but is more optimized for sliding wear resistance and ballistic protection.

5. Applications

Both NM500 and AR500 are used in industries where abrasion resistance is critical:

-

NM500 Steel Plate Applications:

-

Mining equipment and crushers

-

Excavator buckets and loaders

-

Dump truck bodies

-

Construction machinery parts

-

-

AR500 Steel Plate Applications:

-

Shooting range targets and armor plates

-

Ballistic protection panels

-

Industrial wear parts

-

Heavy-duty agricultural equipment

-

6. Availability and Selection

-

NM500: Best sourced in China, with competitive pricing for large projects.

-

AR500: Easier to source in North America and many international markets, often in smaller quantities for specialized uses.

7. Conclusion

NM500 and AR500 wear-resistant steel plates offer similar hardness, abrasion resistance, and strength, making them suitable for demanding environments. The main differences lie in manufacturing standards, impact toughness, and availability.

When choosing between the two:

-

Select NM500 if you require higher impact toughness and are sourcing from Asia.

-

Choose AR500 if you need ASTM-certified material with widespread international availability.