BY  GENN

GENN

2025/10

Blog

NM450 Wear Resistant Steel

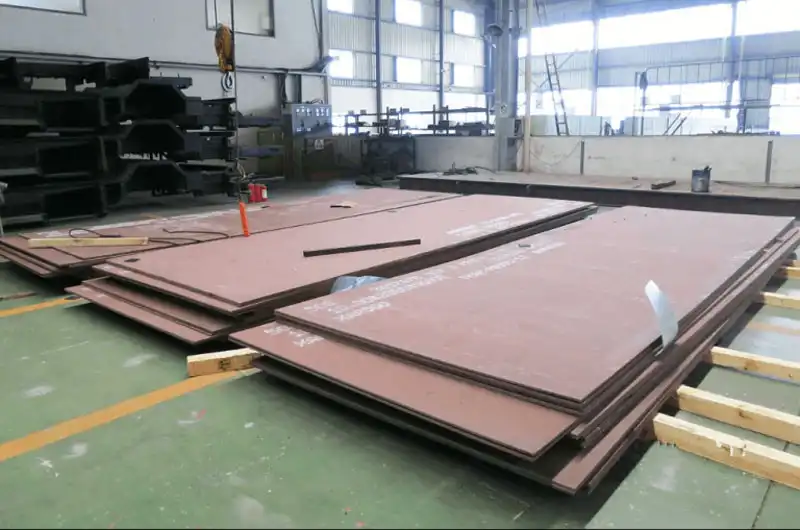

NM 450 plates refer to a specific type of abrasion-resistant steel plates that are widely used in various industrial applications where resistance to wear and tear is crucial. These plates are crafted from high-quality raw materials and are designed to withstand abrasion, making them ideal for use in environments where equipment is subjected to constant friction, impact, and wear.

One of the key characteristics of NM 450 plates is their exceptional hardness. These plates are engineered to possess a hardness level of around 450 Brinell hardness HBW, which is achieved through a specialized heat treatment process. This high level of hardness ensures that the plates can effectively resist abrasion from various sources, including sand, gravel, minerals, and other abrasive materials commonly encountered in industries such as mining, construction, and manufacturing.

Moreover, NM 450 plates offer excellent toughness and impact resistance in addition to their hardness. This combination of properties allows these plates to maintain their integrity and structural strength even under extreme conditions, minimizing the risk of deformation or failure. As a result, equipment and machinery components lined or constructed with NM 450 plates can operate reliably and efficiently over extended periods, leading to increased productivity and reduced maintenance costs.

NM 450 Plate Specification :

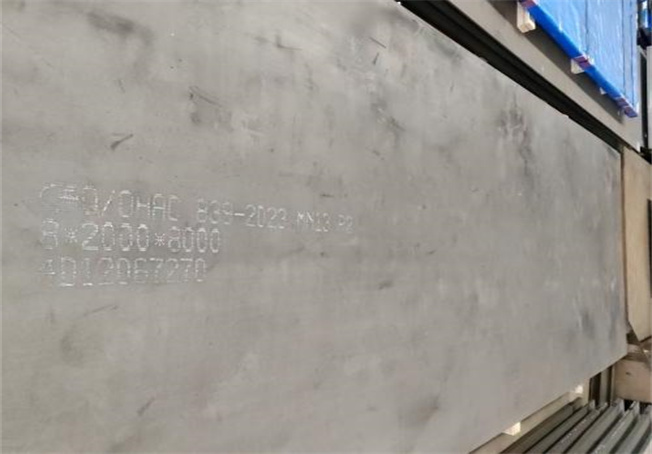

Item: NM 450 Abrasion Resistant Plate

Thickness : 1.2mm-300mm

Length : 50mm-18000mm

Width : 50mm-4020mm

Production : Hot-Rolled (HR)

Standard : JIS G4051 GB711 YB/T107 ASTM

Hardness : Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

Applications : concrete industry, metallurgy, fan industry, coal industry, mining machinery, construction machinery,etc.

Heat Treatment: N, Q+T

Material : NM 450 Plates, NM 450 Abrasion Resistant Steel Plates, NM 450 Wear Resistant Plates

NM 450 Plates Chemical Composition

| Plate | C | Si | Mn | P | S | Cr | Ni | Mo | B | CEV | CET |

| thickness mm | max % | max % | max % | max % | max % | max % | max % | max % | max % | typv | typv |

| 3-(8) | 0.19 | 0.7 | 1.6 | 0.025 | 0.01 | 0.25 | 0.25 | 0.25 | 0.004 | 0.41 | 0.30 |

| 8-20 | 0.21 | 0.7 | 1.6 | 0.025 | 0.01 | 0.50 | 0.25 | 0.25 | 0.004 | 0.47 | 0.34 |

| (20)-40 | 0.23 | 0.7 | 1.6 | 0.025 | 0.01 | 1.00 | 0.25 | 0.25 | 0.004 | 0.57 | 0.37 |

| (40)-50 | 0.23 | 0.7 | 1.6 | 0.025 | 0.01 | 1.40 | 0.25 | 0.60 | 0.004 | 0.59 | 0.36 |

| (50)-80 | 0.26 | 0.7 | 1.6 | 0.025 | 0.01 | 1.40 | 1.00 | 0.60 | 0.004 | 0.72 | 0.41 |

NM 450 Plates Mechanical Properties

| Thickness/mm | ReL /MPa | Rm /MPa | A/% | Hardness/ HBW10/3000 | Impact -20℃ /J |

| 8 | 1250 | 1460 | 16 | 445 | 40 |

| 12 | 1290 | 1470 | 17 | 462 | 43 |

| 20 | 1370 | 1450 | 17 | 473 | 42 |

| 25 | 1230 | 1480 | 16.5 | 465 | 43 |