BY  GENN

GENN

2026/01

Blog

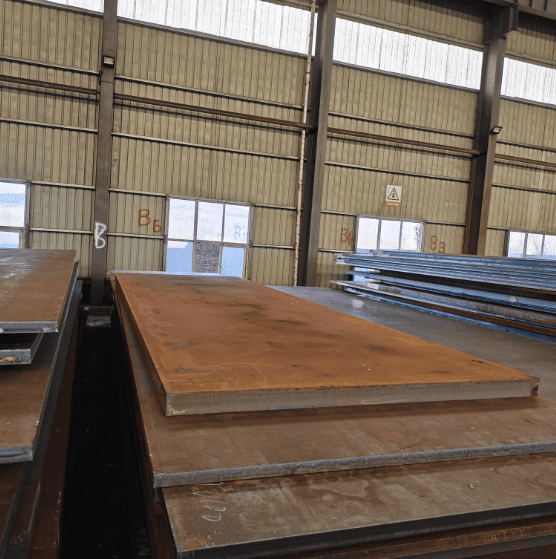

AR500 Abrasion Resistant Steel Plates

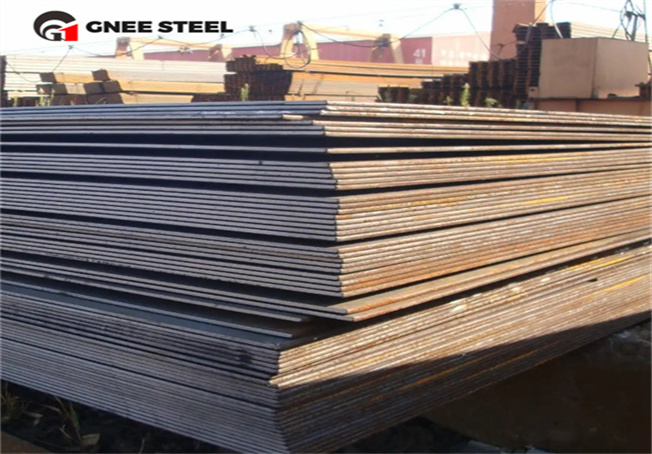

Gnee Abrasion Resistant (AR) steel plates are typically produced in the as-rolled condition and engineered for extended service life in demanding conditions.

These high-performance steel products are ideal for applications in mining, quarrying, conveyors, material handling, construction, and earthmoving equipment.

Engineers and plant operators select Gnee AR steel plates to maximize the lifespan of critical components while reducing the overall weight of machinery units.

Composition and Key Properties of Gnee AR500 Steel

Gnee AR500 is a high-carbon steel alloy renowned for its exceptional hardness and wear resistance. Designed to endure the most abrasive environments, Gnee AR500 steel plates provide long-lasting performance for critical industrial applications.

Unlike conventional steel, abrasion-resistant plates are not governed by a specific ASTM standard. Manufacturers, including Gnee, often produce proprietary AR steel distinguished by a brand name and its Brinell hardness rating (HB).

In engineering, abrasion-resistant steel is also referred to as:

-

AR plate steel

-

Wear-resistant steel plate

-

High-hardness steel plate

These steel products are designed for prolonged durability in abrasive conditions and are widely applied across industries such as mining, process plants, material handling, construction, and earthmoving.

Employing wear-resistant steel reduces unscheduled downtime, extends equipment life, and improves reliability in operations involving impact and sliding contact with abrasive materials.

Gnee AR400 Abrasion Resistant Steel

-

AR400 Wear Resistant Plate

-

400 HB Brinell Plate

AR steel plates are often identified by brand rather than international standards, with hardness ratings in Brinell units. Higher hardness improves wear resistance but can increase fabrication difficulty. For this reason, 500 HB steel is the most commonly specified, offering an optimal balance between durability and workability.

Industrial Applications of Gnee AR500 Steel

Gnee AR500 and AR400 steel plates are ideal for industries where high abrasion is anticipated. The benefits include prolonged service life, improved reliability, and enhanced structural safety. Typical applications include:

-

Mining Industry: Dump truck liners, chutes, conveyors, and other equipment handling abrasive materials.

-

Construction: Bulldozer blades, crushers, and earthmoving machinery requiring wear-resistant surfaces.

-

Military & Law Enforcement: Ballistic plates for body armor and armored vehicles due to high impact resistance.

-

Agriculture: Plows, tillage machinery, and soil-contact equipment exposed to abrasive conditions.

-

Heavy Wear Platforms & Industrial Hoppers: Feeders, funnels, and transfer chutes in material handling operations.

Gnee AR500 vs. Other Abrasion Resistant Steels

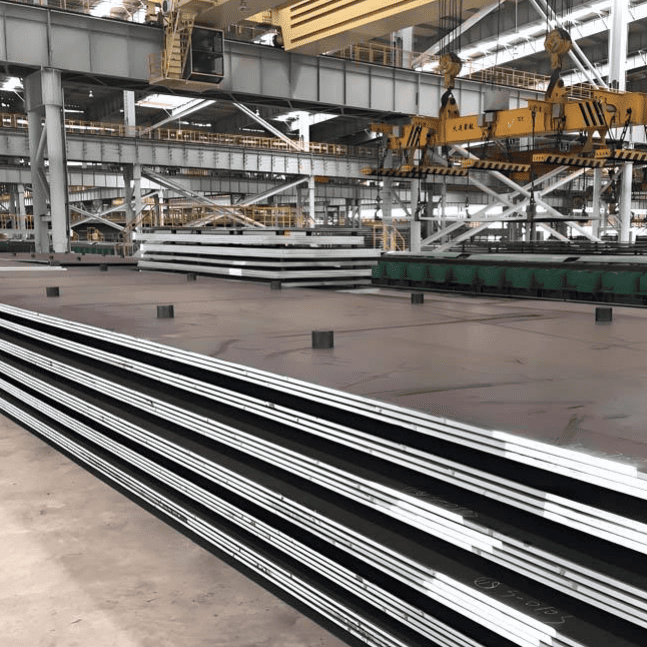

Gnee manufactures a full range of AR steel plates, including AR400 and AR500, each designed for specific hardness and mechanical properties. While both grades are used across similar industries, differences in chemical composition and mechanical characteristics make them suited to distinct applications, such as power generation, oil and gas, and heavy machinery.

Maintenance and Care for Gnee AR500 Steel Plates

Proper care ensures optimal performance and longevity of AR500 steel plates. Gnee provides comprehensive guidance:

-

Corrosion Protection: Apply protective coatings or paints to prevent rust, especially in moist or corrosive environments. Store plates in a dry, covered area when not in use.

-

Welding & Cutting: Follow Gnee’s recommended procedures and use equipment suitable for high-hardness steel to maintain integrity.

-

Repair & Replacement: Small cracks can be welded by skilled technicians. Replace plates if wear exceeds acceptable limits to avoid safety risks and operational failure.

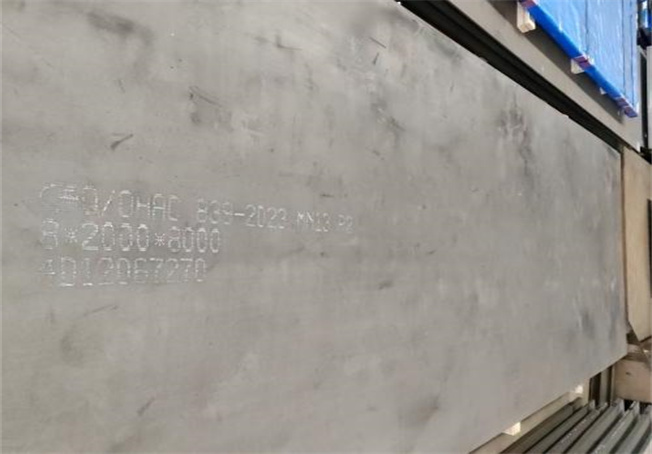

Technical Specifications and Testing

-

Quenched and Tempered: Hardness improved while maintaining toughness.

-

Temperature Limit: Not recommended for use above 250°C to preserve material properties.

-

Testing & Certification: Ultrasonic tested per SA 578 or customer requirement, MTC per EN 10204 / 3.2, Charpy impact tested at -20°C / -46°C, furnace normalized.

Representative Hardness (HBW) Ranges for AR400 Plates:

| Grade | Product | Thickness (mm) | Hardness (HBW) |

|---|---|---|---|

| 400AR | Cut Lengths | 2.5 – 6.4 | 360 – 420 |

| 400AR | Heavy Plates | 5 – 15 | 360 – 420 |

| 400AR | Heavy Plates | 15 – 30 | 360 – 450 |

| 400AR | Heavy Plates | 30 – 60 | 360 – 480 |

Chemical Composition of AR400:

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | B |

|---|---|---|---|---|---|---|---|---|---|

| 400AR | 0.25 | 0.7 | 1.7 | 0.025 | 0.015 | 1.5 | 0.7 | 0.5 | 0.005 |

Mechanical Properties (Typical, 20mm):

-

Yield Strength: 1000 MPa

-

Tensile Strength: 1250 MPa

-

Elongation: 10%

-

Impact Strength: -40°C Charpy V

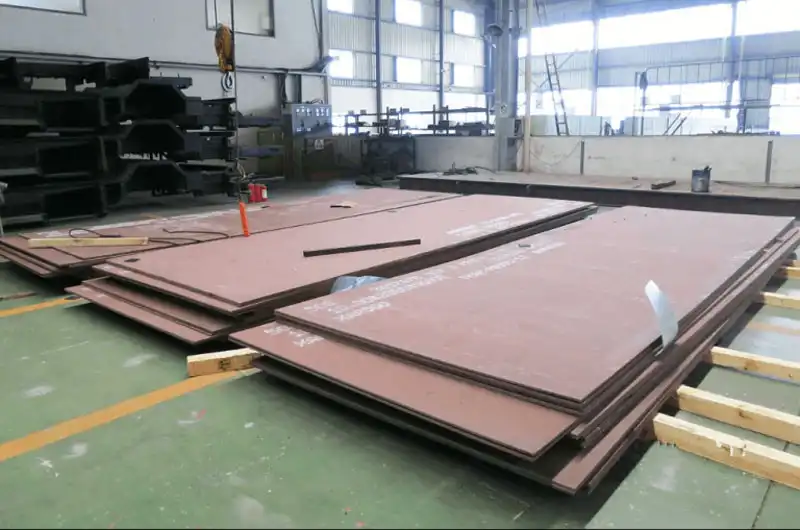

Packing & Delivery of Gnee AR400 Steel Plates

-

Individually sleeved in plastic, wrapped in waterproof material, bundled with nylon rope, labeled for easy identification.

-

Bundles protected against weather, containerized, and shipped globally.

-

Delivery: 10-25 days depending on stock availability.

Packaging Options:

-

Hexagonal bundles

-

Wooden boxes or crates (steel/wood)

-

Special U-Bend tube crates with separators

-

Custom packaging per ASTM A516 or customer specification

Gnee AR500 and AR400 abrasion resistant steel plates combine high hardness, toughness, and long-term reliability, making them the preferred choice for industries demanding wear-resistant solutions.